Feed manufacturers and farmers have choices to give protection to cattle, says Rob Patterson

Feed manufacturers and farmers have sound choices to mitigate in-feed trypsin inhibitors (TI), to give protection to towards those anti-nutritional components undermining cattle efficiency and profitability, says a feed knowledgeable.

Rob Patterson, VP of Innovation and Commercialization with CBS Bio Platforms, has tested the query of whether or not TI publicity – associated with expanding use of different protein resources – is being overpassed, in a three-part sequence of articles.

In Section I he equipped an summary of the problem and why those anti-nutritional components must be controlled. In Section II he mentioned detection and tracking choices. Now in Section III he delves into the overall step in managing TI – the implementation of a number of mitigation methods.

“The excellent news is feed manufacturers and farmers have efficient choices to mitigate in-feed TI,” says Patterson. “The use of a mix of methods the place conceivable is in most cases the most productive strategy to organize the chance and reduce any possible losses.”

(Listen insights from Patterson in the most recent The Sioux Country Ag Heart Podcast.)

Feed method choices

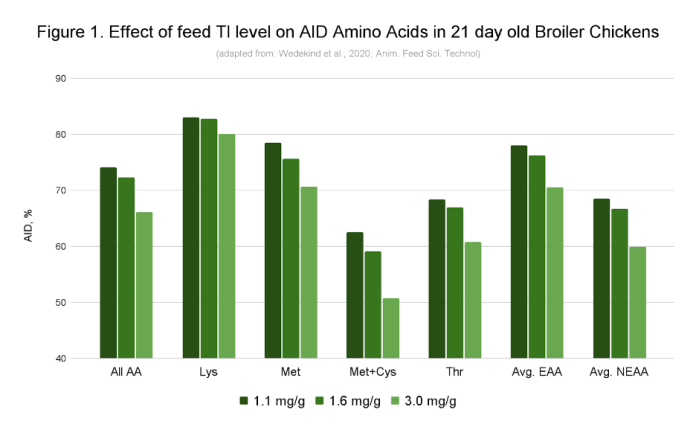

The specter of TI has risen to the leading edge with expanding use of different protein resources, according to price pressures. The use of choice soybean substances corresponding to cooked, complete and entire fats soybeans in addition to expelled and extruded soybean meal, comes with larger TI publicity that may cut back feed high quality for pigs, poultry and ruminants.

As soon as a tracking program is established and verified, one strategy to imagine is managing TI publicity by the use of feed method, says Patterson. This comes to integrating element and ultimate feed TI ranges into current method device systems, to allow methods corresponding to having a most price that will cause element rejection previous to being made to be had into a last feed.

On the other hand, that is “more straightforward stated than accomplished,” he notes, as a result of “the volume of TI appropriate in ultimate feeds is a nebulous quantity and depends at the species being fed in addition to the level of manufacturing.”

Feed processing generation

Another choice is the usage of feed processing generation, as an example the usage of warmth and power remedy of the overall ration by the use of a pellet mill, expander or extruder.

Patterson notes the prematurely and habitual prices related to apparatus set up, repairs and control may well be prohibitive. On the other hand, the manner may well be possible if this apparatus is already in position for the control of feed-borne pathogens corresponding to Salmonella.

Enzymes benefit

Any other solution to organize TI in business feed manufacturing is the usage of exogenous enzyme generation. “Even supposing the everyday use case for nutritional enzymes is for bettering nutrient digestion and feed potency, there’s a rising frame of proof that means that the use of sure proteases can enzymatically denature feed TIs.”

The enzyme manner has a tendency to have a price benefit, Patterson notes. “It may be mixed with further feed method methods to lead to considerable financial savings on a according to tonne of feed foundation.”

Learn Rob Patterson’s in-depth Section III article for complete insights on in-feed mitigation choices, together with main points at the bodily construction of soybean TI and the mechanism of motion underpinning enzyme effects.