Again in 2017, Vikrant Singh and Utkarsh Singh, engineering scholars at Haryana’s BML Munjal College (BMU), have been creating an electrical racing automobile for a contest organised through Baja SAE (Society of Car Engineers) India — a non-profit engineering and clinical society devoted to the mobility group in India.

“It’s a contest the place faculty scholars design and broaden automobiles and compete on automotive racing circuits just like the Buddh Global Circuit. It’s an excellent programme for budding engineers,” recollects Utkarsh, in a dialog with The Higher India.

A key element of creating an electrical racing automobile was once putting in a lithium-ion (Li-ion) battery. On the other hand, discovering this sort of battery in 2017 wasn’t simple as a result of, again then, no one in India was once production it on an important scale. However they sooner or later discovered an organization in Ludhiana, Punjab, which was once uploading batteries and distributing them all over the place the rustic.

“As scholars, we approached that corporate for a battery and so they even agreed to offer us one for this venture. However for 6 months they saved delaying the supply of this battery, and sooner or later, we couldn’t take part within the pageant. Annoyed through this end result, Vikrant and I started discussing why those Li-ion batteries aren’t being made in India,” he recollects.

“We realised that during those batteries you’ve Li-ion cells and those aren’t manufactured in India for the quite simple explanation why that you’ll’t in finding the uncooked fabrics, i.e. lithium, cobalt and nickel, required to cause them to. Additionally, on the time, electrical automobile (EV) intake wasn’t too heavy and nobody realised that this sector would take off quickly. On the time, no matter OEMs (authentic apparatus producers) in India wanted, they have been uploading the ones fabrics,” he provides.

As a part of their faculty semester venture, they made up our minds to construct Li-ion cells at a Rs 200 crore R&D laboratory arrange on campus. “We ordered lithium and cobalt from China. Because of quite a lot of causes, those fabrics didn’t arrive on time for our venture. To finish it, we purchased some previous Li-ion cells from the marketplace, extracted no matter fabrics lets in very impure bureaucracy after which fabricated Li-ion cells (part cells) that delivered some power,” he recollects.

“To obtain those fabrics in India, we had to get started recycling previous Li-ion batteries. We predicted that numerous Li-ion batteries are going to go into the rustic, and if we recycle them, those fabrics will also be reused to make cells. See, you’ll recycle metals like lithium infinitely. That’s how the speculation of BatX Energies was once born. We spent the next semesters researching what’s required to recycle Li-ion batteries on a bigger scale,” he provides.

After faculty, Vikrant and Utkarsh have been very transparent about finding out what it takes to run an organization earlier than beginning one. They labored for a little bit over 365 days in numerous firms with Vikrant engaged in R&D paintings whilst Utkarsh handled the control facet of items.

Amid the pandemic in July 2020, they were given again in combination and established BatX Energies, which is these days a significant Lithium-ion battery recycling startup which produces battery-grade fabrics.

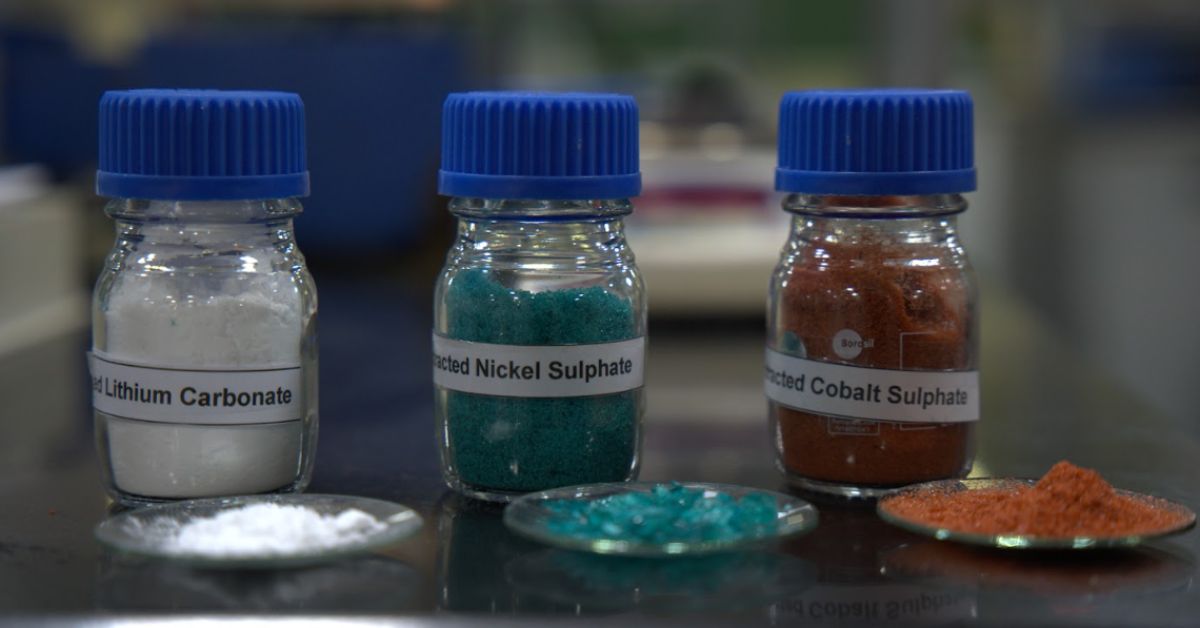

Certainly one of their core targets is to create a home round provide chain of fabrics like lithium, nickel and cobalt, amongst others, and reduce the requirement for mining them. The corporate extracts uncommon earth metals, similar to lithium, cobalt, nickel and manganese from used Li-ion cells, which might be then purchased through quite a few industries — together with EVs, prescription drugs, electroplating and fertiliser. But when those used cells have some price left, they repurpose them into batteries for off-grid sun EV chargers, inverters, or different packages.

The startup has advanced an leading edge process for recycling quite a lot of batteries, using specialized tactics and complex hydrometallurgical processes. As a significant provider of sustainable battery answers in India, they’ve even secured a patent for his or her 0 Waste-0 Emission Era and effectively recycled about 220 million batteries to this point.

recycle and repurpose used Li-ion batteries?

The method starts with sourcing used Li-ion batteries from formal entities like EV producers and ventures engaged in development desk bound packages like telecom towers the place those batteries are deployed, energy electronics, and different digital gadgets like laptops, cellphones, and many others. Additionally they supply those batteries from the casual sector as effectively.

“These days, about 80% of the sourcing of battery cells comes from the unorganised sector as a result of a majority of them are extracted from cellphones and laptops. On the other hand, our marketplace analysis means that the organised sector will quickly overtake the unorganised sector with regards to sourcing those used batteries. Not like pc or telephone batteries, EV batteries can’t be left within the unorganised sector. They don’t have the capability or capacity to care for them. One tonne of Li-ion battery waste is identical to one e-bus battery; 3 EV automobile batteries; 29 three-wheeler batteries; 40 two-wheeler batteries; or 22,000 cell phone batteries,” explains Vikrant.

“As soon as sourced, it’s important to organise secure transportation of those previous Li-ion batteries. We pay shut consideration to the packaging of the battery pack, discharging the battery on the assortment level, making sure no wiring is saved open or uncovered and all of the charging and discharging slots are well-capped. We’ve made certain to apply those fundamental protection measures,” claims Utkarsh.

Even if the startup is based totally out of Gurugram, Haryana, its primary recycling facility lies in Sikandrabad close to Bulandshahr, Uttar Pradesh. There are two issues that occur right here.

As soon as those used batteries succeed in the BatX facility, they’re going to damage them down into other modules and cells, run them thru a sequence of checks, and behavior an research of the mobile efficiency. If a few of these cells nonetheless have some price left and will carry out for some other lifestyles in a special utility, the BatX crew repurposes them for second-life packages.

“For instance, you’ve a mobile, which will also be reused for a torch or in a small digital instrument. If it’s a four-wheeler battery, we will reuse its cells in an power garage utility. We intently gauge how a lot price stays on this battery. The use of our IoT gadgets, we want to be very certain when the battery is coming to the top of its moment lifestyles. It’s an important a part of the method. If there’s a malfunction, we restore it. As soon as the ones cells were exhausted, alternatively, we take them for recycling. If those cells can’t be reused as in line with our first overview, we take them in an instant for recycling. That’s the way you create a round economic system,” he provides.

From second-life EV batteries, as an example, BatX Energies has constructed 100% off-grid sun EV chargers for EV OEMs like MG Motor. They have got even advanced house inverters using second-life EV batteries on the identical price as a lead-acid inverter, which is hazardous.

“We’ve advanced a small unit which is able to run for 5 years. We’re going to deploy those inverters quickly in rural Rajasthan and Madhya Pradesh. As soon as those second-life batteries come to the top in their lives, we will be able to take them again and recycle them,” notes Utkarsh.

As soon as the batteries are deemed no longer are compatible for second-life packages, they’re dismantled, discharged, and overwhelmed into powder at their facility in Sikandrabad, Uttar Pradesh. They name this overwhelmed powder ‘black mass’, which is then transported to their primary chemical recycling facility, and right here, they extract fabrics like lithium, cobalt, nickel, and many others.

“From the black mass, all battery grade subject material together with graphite is got rid of, after which impurities like aluminium, copper and cake. After this, we extract lithium, nickel and cobalt. After we extract those fabrics, we promote them to subject material refiners who use them to make new Li-ion cells. However fabrics like lithium are extensively utilized within the pharmaceutical business to make anti-depression drugs, and many others. Cobalt, in the meantime, is used within the ceramic and ache business whilst Nickel is hired in electroplating and the fertiliser business as effectively. We most effective produce high-grade subject material (99.6% purity),” claims Utkarsh.

Vikrant is going on to say that the method they’ve advanced to repurpose or recycle those previous batteries is chemistry-agnostic — whether or not they’re lithium iron phosphate (LFP) batteries, lithium nickel manganese cobalt (NMC) batteries, Li-ion batteries, or lead acid batteries.

“It took us 5 years to design and broaden this procedure we have now established. We recently have a patent on our ‘Waste to 0 Emission Era’. The patent is on their equipment, strategies and procedure. Since we first of all didn’t have sufficient finances, we advanced the recycling plant ourselves. We’ve no longer imported any of the equipment in our manufacturing plant,” claims Vikrant.

Within the close to long run, alternatively, BatX will glance to change their operations according to a hub and spoke fashion. Even if their primary centre of operations lies in Sikandrabad, UP (Hub), they’re making plans to arrange other amenities (spokes) in puts like Hosur in Karnataka, Siliguri in West Bengal, and Gujarat. Why are they adopting this new running fashion?

“Let’s say, we acquire previous Li-ion batteries from Maharashtra however need to delivery them to our hub in UP. Regardless of all of the protection measures we take, there may be some possibility fascinated with transporting them. That’s why we’re making plans to create amenities (spokes) in states like Gujarat (and West Bengal, Karnataka) in order that we will delivery our previous batteries from Maharashtra there,” he says.

Investment and taking a look forward

In past due December 2023, BatX Energies raised USD 5 million in pre-Collection A investment. The spherical was once led through traders, similar to Zephyr Peacock, but additionally noticed participation from funding platforms like Shall we Mission and current traders like JITO Angel Community, and circle of relatives places of work of Mankind Pharma, Excel Industries, and BluSmart, amongst others.

Within the press free up they issued, Pankaj Raina, managing director of Zephyr Peacock stated, “The corporate is poised to transform a an important stakeholder within the battery provide chain in India, as recyclers can be an important supply of crucial fabrics for Li-ion battery production. We’re excited to spouse with them in this adventure.”

Talking to The Higher India, alternatively, Utkarsh says, “In 5 years, we’re going to recycle roughly 25% to 30% of deployed Li-ion batteries in India. We can provide the fabric again to business gamers who can produce 95% of the battery financial institution again from recycled fabrics.”

(Edited through Pranita Bhat; Photographs courtesy BatX Energies)