Variations in particle dimension inside of a ration can impact each the digestive machine and the efficiency of the chicken

Advent

Feed particle dimension is an often-overlooked facet of poultry manufacturing. Manufacturers will have to now not think that feed is of a uniform dimension and homogeneously combined, or that the feed mill is offering the best mixture of debris in a ration. Feed debris differ in size from very effective to coarse, and other grinding strategies will lead to other particle dimension distributions. Variations in particle dimension inside of a ration can impact each the digestive machine and the efficiency of the chicken, even though the full nutrient values are equivalent. Manufacturers, due to this fact, will have to steadily review feed particle dimension distribution and consider of the various variables that may impact it.

The impact of feed particle dimension at the digestive machine

Digestive tract building is influenced by means of feed particle dimension. Birds eating feed with massive debris will broaden higher and extra muscular gizzards and longer intestinal tracts. Higher feed debris require extra time within the gizzard to grind feed into smaller debris prior to they are able to input into the small gut. Higher feed debris have an extended transit time in the course of the gut. The duration of microvilli within the gut is bigger, which will increase the absorptive floor space, and thereby definitely impacts digestibility and nutrient absorption. Some researchers have speculated that the inclusion of bigger feed debris within the vitamin will increase localized digestive enzyme secretion within the small gut, which advantages total nutrient digestibility.

When the vitamin consists of predominately effective debris those smaller feed debris temporarily go in the course of the gizzard with out grinding and go into the proventriculus. The result’s a small gizzard, enlarged proventriculus and lowered gut duration. Diets containing over the top ranges of good debris will have to now not be fed.

Optimum feed particle dimension

Feed particle dimension of the vitamin performs crucial function in regulating the feed consumption by means of the chicken. Optimum feed particle dimension will increase with age with building of the beak, gizzard and digestive tract. The laying rooster has a choice for higher debris, and the choice grows more potent with age. For the primary six weeks, a starter vitamin is most often given as a disintegrate, which is made by means of breaking apart pellets consisting of good debris right into a disintegrate dimension of one–3 mm. Crumbled feed is perfect for younger chicks as a result of each and every crumb is a composite of various constituents of the vitamin. Persevered provision of crumbs past the starter vitamin reduces the duration of the small gut and dimension of the gizzard.

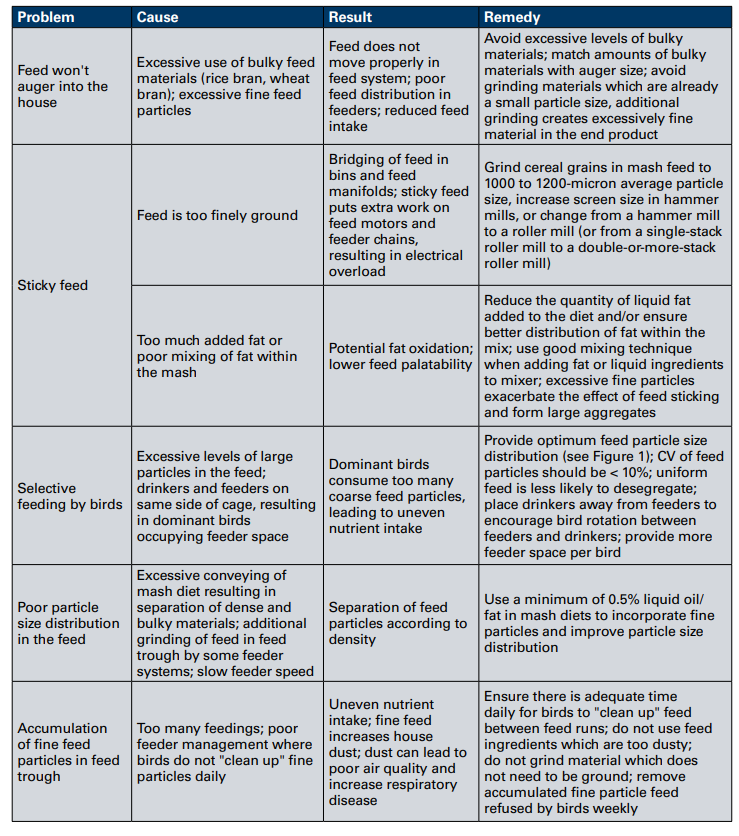

After the starter vitamin, a welltextured mash (meal) vitamin is most well-liked. This guarantees correct building of the digestive tract. Welltextured mash (meal) vitamin has 55–85% of the feed debris between 1 and three mm in diameter, with an approximate Geometric Imply Diameter (GMD) of 1200 microns (see Determine 1). Starting with the pre-lay vitamin, a well-textured mash vitamin comprises massive debris of limestone (2–4 mm diameter). Massive particle limestone is had to take care of just right eggshell high quality.

Selective consuming by means of birds

Mash (meal) feed is most often a mix of coarse and effective debris. Birds preferentially eat higher feed debris. Those massive debris are steadily coarse-ground corn, which is crucial supply of gross power. Wonderful feed debris in most cases include the substitute amino acids, phosphorus, nutrients and hint minerals. The diet/mineral premix is in most cases effective particle. Birds that overconsume higher feed debris most often have prime power consumption and occasional consumption of different vital vitamins, similar to Diet A, diet D, riboflavin, sodium, lysine and methionine. Many egg manufacturing and shell high quality issues are because of inconsistent nutrient consumption led to by means of selective consuming.

Birds which might be fed too usally or in over the top quantity aren’t inspired to devour the effective feed debris. Wonderful particle feed can acquire within the feeders if now not correctly controlled. Inspire the intake of good feed debris by means of leaving an opening of two–4 hours mid-day. This permits birds to scrub the feeders and eat effective debris all over this time. Farmers will have to observe the feed boxes and feeders to evaluate feed disappearance to decide the precise feeding frequency and feed intensity that optimizes the day-to-day intake of each massive and small feed debris.

It’s important that birds eat each massive and effective feed debris each day to verify a balanced nutrient consumption.

Granulometry (figuring out feed particle dimension)

The usual way for figuring out particle dimension is The American Society of Agricultural Engineers (ASAE) process S319.1. (http://animalscience.unl.edu/ Analysis/RumNut/RumNutLab/21-ParticleSizeAnalysis.pdf). The process comes to passing feed or elements via a sequence of 14 monitors (sieves) of regularly smaller diameter for 10 mins. The effects are reported as Geometric Imply Diameter (GMD) and a measure of particle dimension uniformity (usual deviation or coefficient of variation [CV]). Correctly manufactured feed will have to have a CV of much less than 10%. This process is typically simplest completed by means of massive feed turbines.

For analysis of feed particle dimension at the farm Hy-Line has its personal handheld sieve shaker that may decide particle distribution of mash feeds (Determine 1). It is a great tool for farmers to test feed deliveries from the feed mill and test particle dimension within the birds’ feeder.

The impact of milling procedure on feed particle dimension

Uncooked subject material debris go through more than one adjustments in the course of the feed milling procedure. The largest issue affecting particle dimension is how the vitamin is milled. Uncooked fabrics, similar to soybean meal, fishmeal and premixes, are in most cases in a sort that don’t require additional particle dimension relief. Cereal elements (i.e. corn, wheat and different complete grains) of diets at all times go through a grinding procedure. Other aspect varieties will behave in a different way when floor. As an example, wheat will produce a unique particle dimension than corn run via the similar grinder.

Hammer and curler milling are two of the most typical strategies used to grind uncooked fabrics.

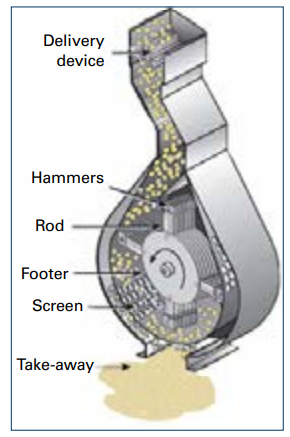

Hammer turbines (Determine 4) are constructed from rotating units of hammers that use affect power to wreck down the grain. The hammers rotate at prime speed and destroy down the fabric till it will probably go in the course of the surrounding display. Particle dimension and uniformity produced by means of a hammer mill depends upon the dimensions, form, velocity and put on of the hammers, in addition to the sort and diameter of the display used. Hammer turbines are ready to supply a variety of particle sizes. They paintings effectively with fiberous fabrics like wheat by-products.

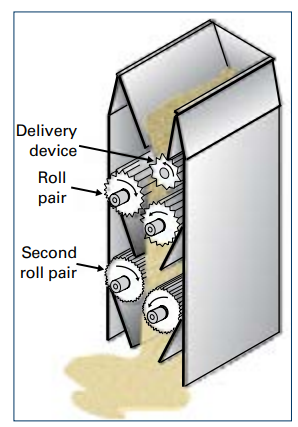

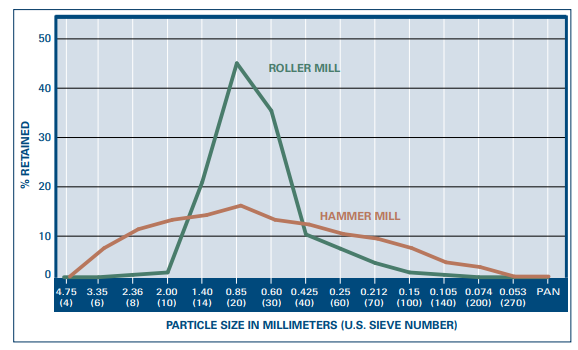

Curler turbines (Determine 5) make the most of cylindrical rollers, in most cases in pairs, to compress and sheer (tear) grains into smaller debris. Feed passes via a sequence of two–6 curler pairs that have corrugations or grooves minimize into the outside. One curler usually rotates quicker and within the wrong way to create sheering power. Particle dimension is decided by means of the selection of rollers, distance between rollers, curler diameter, velocity and corrugation development. Most often, curler turbines grind grain into extra uniformly sized debris than hammer turbines (Determine 6).

Feed supply programs

There are 3 strategies of turning in feed in automatic feeding programs.

Chain sort feeders (Determine 7) – feed is shipped by means of dragging feed across the feed machine with a series. Chain feeders may cause feed debris to split by means of dimension because it strikes feed. The chains can grind the feed debris whilst being conveyed via the machine, even supposing new chain sort programs reduce this impact. Sluggish-moving chain feeders could be problematic as birds in the beginning of a feed line can make a choice out the bigger feed debris.

Auger sort feeders (Determine 8) – an auger is used to distribute the feed. The auger strikes feed extra all of a sudden with much less feed particle separation and grinding than with chain feeders. Auger feeders usually ship much less feed quantity than chain feeders with each and every feeding.

Hopper sort feeders (Determine 9) – a touring hopper distributes feed by means of transferring down the feed line, losing feed by means of gravity. The program reasons minimum separation and grinding of feed debris in comparison to different forms of feeders.

Control of the feeders is vital to reduce the side effects of feed particle separation and save you the buildup of good feed debris. Widespread feedings of smaller amounts minimizes the buildup of good feed. Chain feeders most often ship a bigger quantity of feed, making the buildup of good debris imaginable. Permitting the birds to scrub the feeders day-to-day will save you the accumulation of good debris. Making sure that there’s sufficient feeder area for all birds to devour at one time will create extra uniform nutrient consumption within the flock. Every machine has doable feed particle segregation problems that should be monitored by means of farm managers. Drag chain programs have extra side-to-side segregation, the place the effective debris are concentrated in the midst of the trough, however the higher debris congregate close to the trough partitions. In auger programs, there may be extra top-tobottom segregation, with effective debris settling on the backside of the trough and the higher debris last close to the feed floor. Repeated biking of the auger can scale back this separation.

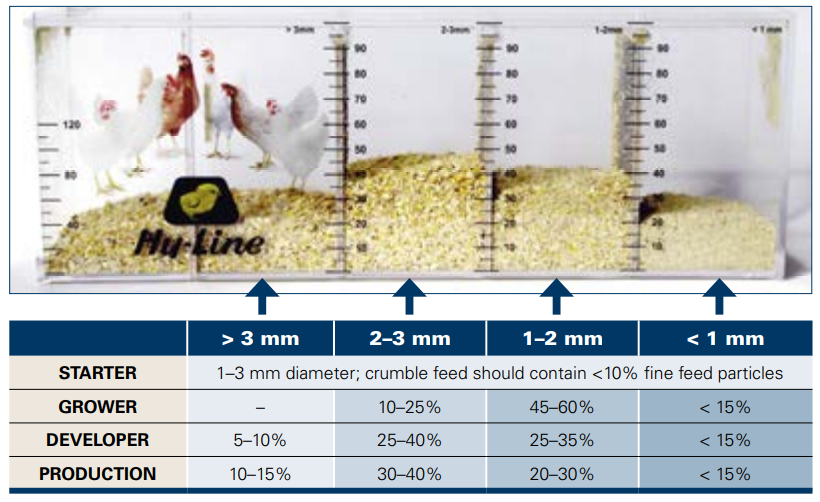

Troubleshooting