On-farm manure remedy may also be difficult for plenty of animal feeding operations, particularly for many who have restricted close by fields for manure land software. Up to now, only a few large-scale animal farms make the most of composting as a long-term remedy for liquid manure.

Composting is a organic procedure wherein microorganisms convert natural fabrics into soil-like subject matter, which will successfully convert animal manure into value-added merchandise. Compost has been well-documented and confirmed to be a very good soil conditioner, which might upload natural subject, strengthen soil construction, cut back fertilizer necessities, and cut back soil erosion doable.

Composting has been going on naturally for thousands and thousands of years. The key distinction between the herbal procedure and the controlled shape is in managing the operational parameters and balancing the uncooked fabrics (feedstocks). The controlled-composting procedure is suffering from a number of elements, similar to ambient temperature, period of various thermal stages, inoculum focus (if any), moisture content material (MC), carbon/nitrogen (C/N) ratio, oxygen focus, turning frequency, pH, particle measurement, and traits of the bulking agent. Beneath managed stipulations, composting is completed in 3 primary stages: emerging temperature, desk bound section, and cooling section. As well as, curing is a important however incessantly omitted level of composting. Along with serving to in compost maturation, curing additional lets in the cardio decomposition of resistant compounds, natural acids, huge debris, and clumps of subject matter that stay after lively compositing.

There are a number of commonplace forms of composting applied sciences utilized in manure composting, together with windrow composting, static pile, aerated pile, mixing-vessel, and in-vessel.

The blending-vessel and in-vessel composting are jointly referred to as strategies that confine the composting fabrics inside a construction, container, pit, or vessel and depend on more than a few compelled aeration and mechanical turning ways to hurry up the composting procedure. Consequently, mixing-vessel and in-vessel composting may also be extra environment friendly (brief composting length) than the opposite composting strategies, together with passive and windrow composting.

Compost-A-Matic is a composting machine that automatically mixes and aerates compost fabrics in concrete pits. The composting techniques be offering each choices of constant drift composting (including subject matter within the compost pit day by day) and batch composting (filling all of the pit with subject matter best as soon as, and turning/aerating the fabric till composted). On the other hand, the continual drift possibility is extra common because of the simplicity of including natural subject matter incessantly. A 7-foot-long pit (channel) house is created on the entrance finish, and natural subject matter is added each time the compost turner mixes and turns the compost. Restricted farm animals farms, particularly business pig farms, have automatically used mixing-vessel composting techniques to control their manure. The aim of this situation find out about used to be to focus on some facets of machine design, operation, and control of a mixing-vessel composting machine at a big swine completing farm.

Swine farm and composting facility

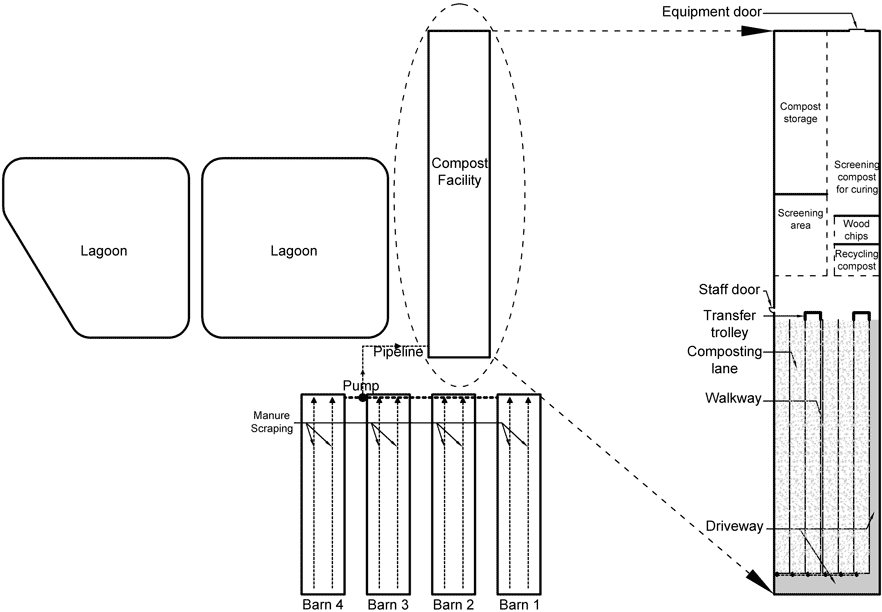

The blending-vessel composting machine used to be used at a business swine farm that used to be situated within the Midwest and handled the manure produced through as much as 24,000 head of completing swine. There have been 4 an identical wean-to-finish barns with a minimum of 5 weeks of age distinction, and every barn had 4 an identical rooms housing 1,500 heads of swine every, Determine 1. A confined facility used to be constructed for the swine manure remedy with a mixing-vessel composting machine: Compost-A-Matic. The format of a piece of the farm and an in depth plan comic strip of the composting facility is proven in Determine 1.

A manure scraper machine got rid of the swine manure beneath the slatted flooring, in a shallow gutter machine with out requiring extra water. The manure scraping time of the swine barns used to be normally a couple of times in keeping with day and may also be versatile consistent with the manure manufacturing and composting operation. Scraped manure from the 4 barns used to be amassed right into a centralized assortment pit. The manure used to be then pumped via a boost station and pipeline to the composting facility. In case of failure of the manure composting machine, two lagoons had been additionally to be had at the farm. A three-ft vast walkway used to be integrated between the 3rd and fourth composting pit row for repairs and aeration pumps and pipes. A fifteen-ft vast driveway for the front-end loader to convey the carbon fabrics used to be integrated within the southeast aspect and south finish of the composting facility, Determine 1.

In the past, a sloped display separator (Key Greenback, Parkville, Missouri) used to be used to scale back one of the vital water within the manure sooner than pumping it into the composting channels, however the display separator used to be now not correctly sized and used to be deserted. It’s famous that biosecurity is a big attention within the design and operation of composting techniques and {that a} Danish access machine used to be used to verify a line of separation for the composting facility.

The scale of the composting facility had been suitable, 800 feet × 150 feet × 20 feet (period × width × sidewall peak). The peak of the sidewall used to be designed to deal with the peak of the front-end loader. The composting facility used to be designed and built as a metal body. The inner house used to be divided into two portions of just about the similar measurement through the team of workers door, one aspect is used for the composting lanes, and the opposite aspect is used for the follow-up operations, together with screening, curing, and garage (proven in Determine 1).

The composting barn used to be in-built 2011, and no contractor used to be used. In 2021, the method produced 7,500 yards3 of compost from all of the manure from the completing barns with 24,000 heads.

Blending-vessel composting important

The blending-vessel compost machine makes use of a shallow pit design to biologically stabilize natural subject matter with/with out compelled aeration. The industrial supplier for the composter is Aggero, LLC., a newly named waste control department of Farmer Computerized of The us, Inc. The corporate is situated in Statesboro, Georgia, and makes a speciality of animal farm apparatus, particularly for the poultry business.

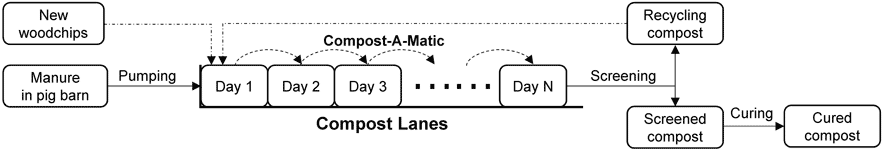

A continuing drift composting mode used to be decided on within the swine farm, and the mixing-vessel composting procedure is gifted in Determine 2. A Compost-A-Matic 610M agitator used to be used to combine and transfer the compost ahead day by day and to make space close to the entrance finish of the compost pit through the manure inlet for loading the scraped manure and woodchips.

Generally, constant and excellent high quality compost begins with mixing uncooked fabrics to care for a C/N ratio of 25:1 to 30:1, which is regularly believed to be the best vary for lively composting. On this mixing-vessel composting machine, recent woodchips had been used as a carbon supply because of their native availability. Native city wooden waste used to be transformed into woodchips the usage of a bath grinder with a mesh measurement of 2 inches. On the rear finish of the compost pit, the compost used to be screened the usage of a mesh measurement of 2 inches and separated into finer compost and coarse compost. The finer compost used to be then moved to a pile for curing, and the coarse fabrics had been added again (recycled) to the pit rows together with recent woodchips for additional composting. The swine farm’s compost components integrated one scoop (roughly 4 backyard3) of clean woodchips, two scoops of coarse (screened) compost, and one scoop of excellent compost. The tremendous compost used to be added to lend a hand give you the microbes to strengthen the composting procedure. The quantity ratio of the uncooked swine manure and carbon fabrics used to be about 1:1. After about 55 days of blending and composting, the compost was much less wet and used to be screened for both including again to the pits for composting or piled for curing.

On-farm mixing-vessel composting machine design and operation

A rational design of the swine manure mixing-vessel composting machine will have to start with estimating the whole manure manufacturing and frequency of manure elimination and addition to the composting machine. The composting pit rows should be designed to compare the manure manufacturing and fluctuations and emptied incessantly to deal with the newly scraped manure from the pig barns, that have best minimum house for brief manure garage. As well as, the ability wishes to incorporate suitable house consistent with its serve as, together with recent carbon assets, composting, screening, curing, and garage spaces, and to permit motion of the wanted apparatus and to move the switch trolley.

Machine design and working capability

To begin with, the program used to be designed to procedure manure from 3 wean-to-finish with a complete capability of 18,000 head, however the machine if truth be told treated manure from 4 barns, with a complete capability of 24,000 head. The day by day manure manufacturing of the 18,000 (or 24,000) head of wean-to-finish swine used to be 2,520 (or 3,360) feet3 assuming that the manure manufacturing in keeping with pig is 0.14 feet3/d (ASABE same old). Manure is first scraped from the barn day by day (with the exception of on Sunday) and pumped by way of a boost station (Determine 3) via an underground pipeline to the composting facility and composting pit rows (Determine 4).

The width and intensity of the concrete pit rows had been designed and built consistent with the agitator sizes. For this composting web site, two Compost-A-Matic 610M agitators (Determine 5) had been used to combine and aerate the combination of manure and carbon fabrics, every for 3 composting pit rows, respectively. A complete of six composting pit rows with dimensions of 300 feet × 19.6 feet × 3.3 feet (period × width × intensity) had been constructed within the composting facility (Determine 1). The period and selection of composting rows are designed to deal with the day by day manure manufacturing, carbon fabrics, and MCs.

Each and every time when the combination vessel blended the compost, an approximate house of seven feet used to be created on the entrance finish of the pit row, growing about 432 feet3 of house for brand spanking new manure and carbon subject matter addition. There used to be roughly 4,320 feet3 of house to be had in keeping with day for manure and carbon subject matter addition, making an allowance for every compost mixer can combine and aerate 5 turns of the compost pit rows when the farm staff used to be running 18–20 hours in keeping with day. The time had to combine every pit row used to be decided through the period of the compost pit, which used to be suffering from the MC variation. The farmer reported that the compost loses MC quicker all the way through hotter than less warm months.

The day by day manure manufacturing of every 1,000-head completing swine is roughly 170 feet3 (ASABE same old). Due to this fact, the combination vessel measurement and unit quantity variety will have to supply a minimum of 170 feet3 of remedy capability day by day. As an example, for a smaller pig farm of a 4,800-head completing swine operation, one may use just a unit of Compost-A-Matic 310 agitator and a unit of switch trolley whilst the usage of part the width of the compost pit row, and adjusting the pit period, the selection of pit row, and farm team of workers shift hours accordingly.

Composting machine operation

Composting is an cardio procedure which consumes huge quantities of oxygen. The blending-vessel machine advances during the compost rows to supply turning and aerating. This procedure additionally strikes older subject matter to the rear finish of the pit, frequently advancing the compost substrate till turning into a extra strong compost product. Throughout this blending/transferring procedure, the combination paddles get a divorce huge debris to permit most floor space for oxygen touch. Along with offering oxygen, the turning and aerating may additionally take away warmth, water vapor, and different gases trapped throughout the composting piles.

The air provide pipeline on the backside of the lanes (Determine 6) used to be to begin with designed to lend a hand aerate the compost, strengthen the decomposition, and probably shorten the time required. On the other hand, the air provide pipeline’s air outlet holes had been simply blocked, and the combination vessel used to be discovered so as to supply sufficient aeration, thus, the aeration machine used to be ultimately deserted within the early level of the composting procedure.

Turning the compost a couple of times each day used to be reported to be enough for compost aeration wishes and warmth elimination. The employees normally became the compost two times (as soon as in keeping with day), making enough room to deal with the day by day produced manure from the 4 barns. Nearly 4 hours had been required for the combination vessel to show a complete 300-ft lengthy composting row. The composting facility used to be operated on two 10–12 hours shift schedules in keeping with day.

The blending vessel used to be designed to combine every of the 3 pit rows as soon as an afternoon. After that, the agitator used to be shifted to some other composting row by way of a switch trolley (Determine 7), which used to be designed to permit one mixing-vessel machine to serve 3 pit rows separated through the middle walkway. To reduce the trolley switch time, the farm staff incessantly programmed the combination vessel to copy blending the similar pit, thus, some pit rows had been blended two times day by day. The composting facility normally operates six days per week. Due to this fact, the manure used to be now not scraped within the swine barns on Sundays.

City waste wooden used to be amassed from a close-by town and used to be used to organize recent woodchips the usage of a bath grinder. The woodchips had been flooring and screened at a close-by box sooner than being moved to the composting facility. After the preliminary composting throughout the concrete pit rows, or after about 55 days (relying at the feedstock MC and season) of composting, the compost used to be screened and divided into coarse recycled woodchips and tremendous compost for both recycling into the composting procedure or moved into some other phase to be cured (Determine 8).

The composting machine additionally labored as a dehydration machine. The fabric used to be allowed to stick about 55 days within the composting rows to reach 35–45% MC of the substrate. Throughout composting, moisture ranges alternate as water evaporates and a starting MC of 40–65% is a basic advice that works nicely for lots of the fabrics. At MC of not up to 40%, the microbial process slows down, while, at a MC above 65%, water displaces a lot of the air within the pore house of the composting fabrics, limits air motion, and therefore results in anaerobic stipulations. Consistent with the farm, the MC of the pig manure is set 90–97%. Due to this fact, mixing the uncooked fabrics lowered the unique MC of composting substrate. As well as, the construction helped with keeping up room temperatures all the way through iciness months. On the other hand, the compost yield used to be nonetheless two times as a lot in the summertime as in comparison to the iciness.

A part of the screened, finer compost used to be moved to other piles for curing. Curing continues till the MC reaches 30–35%, it used to be reported that the interior temperature of the curing piles may nonetheless achieve 120–130°F. The farmer additionally said that the objective used to be to care for the completed compost to have a MC of round 30% to attenuate the mud all the way through transferring and spreading (land software) within the box.

The paddles of the combination vessels had been normally modified out each 5 weeks, which can be normally made within the farm’s store. A team of workers member maintained the apparatus a minimum of a couple of times per week on the swine farm. {The electrical} machine used to be normally probably the most problematic phase because of the slightly wet and corrosive surroundings. It used to be additionally reported {that electrical} repairs used to be additionally the costliest exertions, in most cases $50+ in keeping with hour, and required just a little extra making plans for biosecurity causes since the electrician additionally labored on different portions of the farm.

The air flow machine of a confined construction such because the composting facility is essential to care for excellent air high quality and thermal stipulations inside of. Within the swine farm composting facility, herbal air flow with sidewall curtain openings (within the sidewall alongside the composting rows) and a ridge vent (during the longitude of the entire construction) had been used when the interior temperatures had been above 85°F. When the interior temperature droppped under 85°F, the barn used to be switched to negative-pressure air flow mechanically. The controller became on a complete of 8 exhaust fanatics (36” diameter) put in on each the top wall and sidewalls of the composting barn. The air flow fanatics had been useful in doing away with an important quantity of gases, moisture, and mud within the air.

Traits and nutrient adjustments all the way through the composting procedure

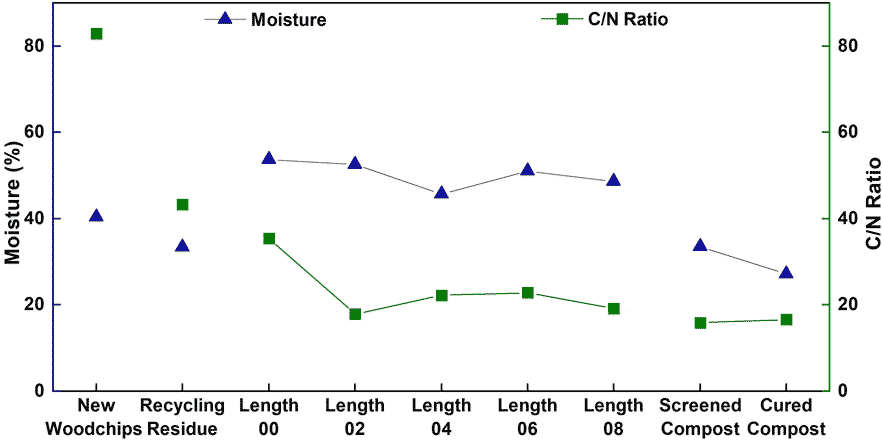

The MC and C/N ratio are an important elements affecting composting. Throughout our talk over with to the composting facility, samples had been amassed from the recent carbon subject matter, screened composts, cured compost, and 5 places which can be uniformly disbursed together with the compost pit row (period 00, period 02, period 04, period 06, and period 08, (Determine 9). As anticipated, MC reduced progressively alongside the compost row, indicating the composting procedure with blending used to be ready to evaporate an important quantity of moisture. In the end, the MC of screened finer compost dropped to under 40%, whilst the MC of cured compost reduced to 27.2%. In the meantime, the MC of the recycling compost used to be less than the recent woodchips, and the blended substrate at period 00 (beginning day). The C/N ratio of recent woodchips used to be greater than 80, indicating that woodchips had been an acceptable substrate as a carbon supply. Once more, the C/N ratio of the recycling compost used to be less than the brand new woodchips however upper than all different substrates, together with the screened and cured compost.

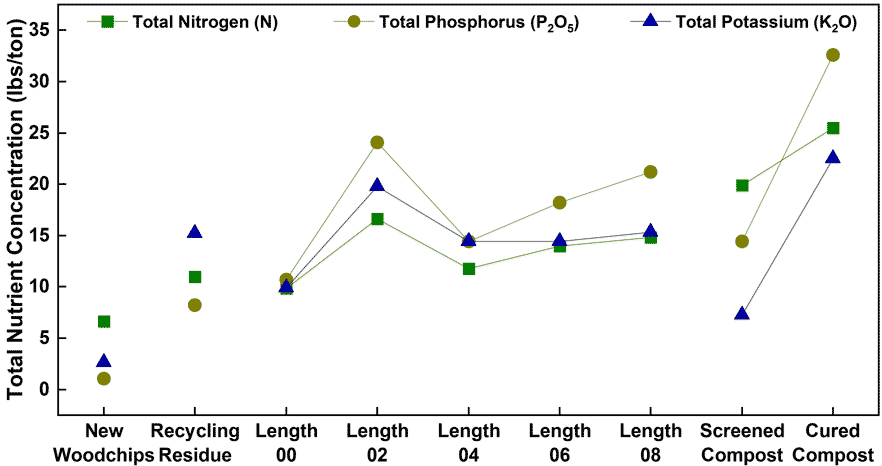

Compost costs are incessantly decided through the crucial vitamins, overall nitrogen (N), phosphorus (P), and potassium (Ok) values. The N, P, and Ok concentrations of all amassed samples had been additionally measured and are introduced in Determine 10. The N, P, and Ok concentrations of the brand new woodchips had been the bottom. That is anticipated on account of the manure addition, and the N, P, and Ok concentrations of the substrate would building up reasonably when the compost shrinks and dries. Thus the N, P, and Ok concentrations of the cured compost had been proven to be the perfect. Plainly, the N, P, and Ok concentrations had been discovered to be carefully correlated to the MC values of the other composting level samples.

Compost high quality and financial analysis

Compost high quality can have an effect on the cost and quantity wanted for land software, which means that completed compost research is incessantly wanted to make sure product protection and marketplace claims. Consistent with U.S. composting council, the American Society for Checking out and Fabrics (ASTM) is the company that publishes Take a look at Means for the Exam of Composting and Compost (TMECC) to supply detailed protocols for verifying the bodily, chemical, and organic stipulations of composting feedstock, subject matter in procedure and completed compost merchandise on the level of sale. Extra regimen research could be wanted if the compost had been to be offered as bagged compost merchandise.

Essential traits and concerns

Along with the foremost vitamins (N, P, and Ok), different traits together with pH, soluble salt, moisture, natural subject, particle measurement, adulthood, balance, heavy metals, bugs, and pathogens, too can affect the standard of compost. As pH is the measure of hydrogen ion process, compost can have an effect on the pH of the soil or rising media relying at the quantity of compost implemented. Soil pH is incessantly adjusted through the usage of fabrics similar to lime (to boost pH) and sulfur (to decrease pH), which is also used to regulate the compost product.

Soluble salts in compost check with the quantity of soluble ions in an answer of compost and water. Even supposing plant species have a salinity tolerance, over the top soluble salts may cause phytotoxicity in vegetation. Standard conductivity values in soil vary from 0 to at least one.5 in maximum spaces of the rustic, while maximum composts have upper salt conductivity. Due to this fact, watering may well be used to scale back the soluble salt content material within the soil.

Generally, MC of 40–50% is beneficial for completed compost. Very dry compost (35% MC or under) may also be dusty and aggravating to paintings with, whilst very rainy compost (55–60% MC and better) can change into heavy and clumpy, making its software harder and supply costlier.

Adulthood is the level or degree of completeness of composting. A unmarried belongings does now not describe adulthood, and due to this fact, adulthood is perfect assessed through measuring two or extra compost traits. Some immature composts would possibly include top quantities of loose ammonia, sure natural acids, or different water-soluble compounds, which will prohibit seed germination and root building or purpose scent. All makes use of of compost require a mature product loose of those probably phytotoxic elements. The steadiness of a given compost is necessary in figuring out the possible affect of the fabric on nitrogen availability in soil or enlargement media and keeping up constant quantity and porosity. Maximum makes use of of compost require a strong to very strong product that can save you nutrient tie-up and care for or strengthen oxygen availability in soil or enlargement media.

Positive heavy metals and hint parts (e.g., boron, manganese, molybdenum, nickel, and selenium) also are recognized to purpose phytotoxic in vegetation, and explicit plant species are recognized to be extra delicate than others. On the other hand, those parts aren’t normally present in compost in unfavourable amounts. All composts containing regulated feedstock should meet nationwide and state protection requirements sooner than being advertised. As well as, the U.S. Composting Council’s Seal of Checking out Assurance (STA) qualified compost should meet the EPA trying out limits for heavy metals.

Pathogens are disease-causing organisms, together with micro organism, viruses, fungi, helminths, and protozoa that could be found in uncooked wastes or by-products. Each plant and human disease-causing pathogens are provide at some background ranges within the surroundings. The composting procedure should get rid of or cut back pathogens to a degree this is under the edge the place the chance of transmitting illnesses will happen. The time-temperature requirement guarantees plant and human pathogen destruction in compost and is regarded as an efficient way to resolve that compost is slightly weed-free. The U.S. Composting Council’s Seal of Checking out Assurance (STA) qualified compost should meet the EPA trying out limits for pathogens.

Financial analysis

The swine farm control built the composting barn themselves in 2011. The composting facility and kit prices totaled $2.5 million, with an equivalent value for every. It is vitally most likely that the similar amenities and kit would value extra lately and be constructed the usage of contractors. A contemporary quote (September 2022) for the Compost-A-Matic 610M agitator used to be $200,000. The farm supervisor estimated that the development value of the composting facility could be 30% upper lately.

The marketplace charge of the compost is $35–$40 in keeping with backyard, consistent with the farm supervisor, which is normally priced in accordance with the N, P, and Ok values. There’s, alternatively, festival from hen clutter which incessantly has upper N, P, and Ok concentrations as crop fertilizer. Researchers from a close-by land-grant college evaluated the composting merchandise and estimated that the compost used to be precious because of the soil modification high quality and really useful micro organism and humic acids. The farm has been promoting one of the vital compost in bulk. The completed composts are basically land implemented to the farm’s 500–700 acres, the place they’re used as soil amendments, and had been particularly useful to the sides of the fields the place manure used to be now not implemented.

Desk 1. Estimated compost source of revenue and expenditures for the composting facility on an annual foundation.

| Source of revenue/Expense | Unit | Quantity |

|---|---|---|

| Compost manufacturing | backyard3 | 7,500 |

| Unit Worth | bucks in keeping with backyard | $35 |

| Attainable compost source of revenue | bucks in keeping with 12 months | $262,500 |

| Collection of workers | – | 2 |

| Unit-payment | wage in keeping with particular person | $48,000 |

| General workers expense | bucks | $96,000 |

| Electrical energy quantities | kW·h | 184,392 |

| Unit-price | bucks in keeping with kW·h | $0.10 |

| General electrical energy bills | bucks | $18,439 |

| Gas quantities | gallons | 14,976 (diesel) |

| Unit-price | bucks in keeping with gallons | $3.30 (diesel) |

| General gasoline bills | bucks in keeping with 12 months | $49,421 |

| Contemporary woodchip prices | bucks in keeping with 12 months | $75,000 |

| Portions and provides | bucks in keeping with 12 months | $30,000 |

| Repairs value, electric | bucks in keeping with 12 months | $5,000 |

| General annual prices | bucks in keeping with 12 months | $273,860 |

Estimated annual bills for the composting facility are indexed in Desk 1. All of the values had been estimated following the recognized working and upkeep prices. The upper prices had been exertions, recent woodchips, and gasoline, about $96K, $75K, and $48K, respectively, in 2021. Each and every of the combination vessels used to be provided with two 10-horsepower agitator motors and a boost/propel motor rated at 2 horsepower. Assuming each mixers perform for 18 hours in keeping with day, that is an identical to 18 hours of operation for 44 horsepower motors (2 × 22 horsepower) every day. This results in {an electrical} want of 591 kW-h/day, with an estimated value of $59.1 for day by day operation, assuming an electrical energy value of $0.1/kW-h. Extrapolating this to a once a year value, leads to $18,439 a 12 months, assuming six running days for the 52 weeks in keeping with 12 months.

Gas intake used to be estimated, assuming the front-end loader used to be working for 8 hours in keeping with day at 4 gallons/hour of diesel, which is 32 gallons of diesel in keeping with day. The screening system used to be operated for two hours in keeping with day, at 8 gallons/hour of diesel, which is 16 gallons of diesel in keeping with day — totaling to fourteen,976 gallons of diesel in keeping with 12 months or $49,421/12 months of diesel for transferring the recent woodchips and compost merchandise and compost screening.

Those prices don’t come with the carbon fabrics wanted. The farm estimated the price of making the recent woodchip at $5/backyard3. The farm used to be estimated to provide 7,500 backyard3 of completed compost in keeping with 12 months. Assuming the compost substrates shrink through 50% conservatively, the recent woodchips wanted may well be

up to 15,000 backyard3. Thus it may be estimated that the recent woodchips would value $75,000/year. If a farm had been to buy woodchips from a provider, the price would rely at the places (distance and transportation prices) and provides of in the community to be had woodchips. The standard woodchip prices vary from $15 to $35/backyard3. The estimated overall annual prices to perform the mixing-vessel composting machine is thus $274K/12 months ($18.4K electrical energy + $49.4K gasoline + $75K woodchips + $30K portions/provides + $5K electric repairs + $96K exertions).

The estimated price for the completed compost used to be $262,500/12 months. This price is estimated in accordance with the common compost manufacturing of seven,500 backyard3 and an estimated price of $35/backyard3, Desk 1. The prices of the compost construction and kit (composters, front-end loaders, compost screening machines, and many others.) aren’t integrated within the desk. Amortization of the construction and kit could be suffering from the lifespan and unique stipulations (one of the vital apparatus had been purchased used). The prices of the land software of the compost had been additionally now not regarded as. The price of putting in and working the mixing-vessel composting machine used to be costlier than the possible woodchip source of revenue in accordance with the present marketplace price.

Conclusions

A mixing-vessel composting machine blended with an automated manure scraper machine, and when slightly reasonably priced woodchips are to be had, can successfully convert the swine manure into precious compost with out generating wastewater. Woodchips paintings really well as a carbon supply because of their top C/N ratios and longer decomposition time, because the hardy woodchips may also be screened and recycled within the composting procedure. Day by day blending looked as if it would supply sufficient aeration for the compost pit rows and didn’t require the pipeline forced-air machine, which used to be simply blocked and required extra repairs.

The compost pits should fit the agitator measurement, and the selection of pits and agitators wanted is determined by the farm measurement and day by day manure manufacturing, which additionally determines the composting facility and important apparatus to transport and display the compost and carbon fabrics. As well as, a well-designed air flow machine combining mechanical and herbal air flow are crucial to care for excellent air high quality and thermal stipulations within the compost barn. In the end, the compost price is determined by overall N, P, and Ok concentrations and the marketplace charge of the fertilizer. Blending-vessel composting may also be expensive and labor-intensive, nevertheless it has a number of advantages. It reduces the desire for long-term liquid manure garage and gets rid of the desire for agitating and making use of huge quantities of deep-pit manure or lagoon effluent at the land. This may also be particularly helpful for animal farms which might be landlocked and going through manure nutrient control demanding situations.

In the end, in accordance with the farm measurement and manure manufacturing, a smaller unit of the combination vessel and custom-design composting barn may well be suited to a completing pig farm as small as 4,800-hd. One of these composting machine blended with a manure scraper machine can alleviate the manure strain through getting rid of all of the liquid manure and convey excellent high quality compost merchandise.

Disclaimer

Citing the product type, logo title, and knowledge on this newsletter are only for readers’ basic passion and comfort and don’t counsel any endorsement through the authors and the College of Missouri.

Acknowledgment

The authors recognize the assistance of the farm control group and native extension college.

References

- ASABE D384.2 MAR2005 (R2019). Manure Manufacturing and Traits. In: ASABE STANDARDS, ASABE. St. Joseph, MI 49085-9659

- Golueke, C. G., & Diaz, L. F. (1990). Figuring out the fundamentals of composting. Biocycle, 31(4), 56–59.

- Gondek, M., Weindorf, D. C., Thiel, C., & Kleinheinz, G. (2020). Soluble salts in compost and their results on soil and vegetation: A overview. Compost Science & Usage, 28(2), 59–75.

- Iowa State College. (2016).

- Rynk, R., Van de Kamp, M., Willson, G.B., Singley, M.E., Richard, T.L., Kolega, J.J., Gouin, F.R., Laliberty, L., Kay, D., Murphy, D. and Hoitink, H.A., (1992). On-farm composting guide (NRAES 54). Northeast Regional Agricultural Engineering Provider (NRAES).

- Seal, A., Bera, R., Chatterjee, A. Ok., & Dolui, A. Ok. (2012). Analysis of a brand new composting means relating to its biodegradation pathway and review of compost high quality, adulthood, and balance. Archives of Agronomy and Soil Science, 58(9), 995–1012.

- US EPA.