The odors and gases produced by means of pigs raised in confinement constructions are a priority for manufacturers running within the constructions and for his or her neighbors dwelling close by. Deficient air high quality within the construction is a well being and wellness factor for staff in addition to the animals dwelling within the constructions, whilst emissions of odors and gases may end up in lawsuits and nuisance proceedings by means of neighbors.

Analysis has proven that sprinkling vegetable oils at the ground and different pen surfaces in swine barns can considerably cut back airborne particulate topic (mud) concentrations. In a learn about lately performed in northern Missouri, sprinkling soybean oil as soon as an afternoon in a swine completing barn considerably lowered overall suspended particulates (TSP) and particulate topic lower than 10 microns in diameter (PM10). At an general operational charge of about $1 in line with pig area (about $0.40 in line with completing pig) for the elemental oil sprinkling gadget, this generation seems to be cost-effective for swine manufacturers.

Assets of mud, scent and gases

Mud in swine confinement constructions is composed of a spread of natural parts, together with fecal fabrics, feed debris, animal dander, molds, pollen and bug portions. Gases, similar to ammonia, hydrogen sulfide, carbon dioxide and methane are the results of anaerobic decomposition of manure and urine. Odors are created by means of unmarried gases or combos of gases and are continuously transported by means of mud debris between 5 and 20 microns (µm) in diameter.

Advantages of controlling mud, scent and gases

A top prevalence of signs very similar to persistent bronchitis has been discovered amongst employees in swine confinement constructions, and long-term measurements of air emissions from swine amenities have proven that scent, particulate topic and fuel emissions could also be important, particularly at massive websites. Mud too can act as an irritant to the respiration tract of animals, doubtlessly affecting their well being and enlargement fee.

Mud debris smaller than 10 µm in diameter will deposit within the nostril; debris between 5 and 10 µm in most cases collide with the mucous lined wall of the respiration tract and can deposit within the higher respiration tract, or the nostril, throat, trachea and bronchi; and debris smaller than 5 µm can penetrate into the lungs. Due to this fact, those debris are all thought to be respirable.

Effectiveness of oil sprinkling

A number of components are necessary to the effectiveness of vegetable oil sprinkling. Any vegetable oil freed from debris and coffee in vegetable scent can be utilized (with attention of its combustibility) if the garage amount is huge. Soybean oil is most often decided on as a result of it’s regularly to be had. Soybean oil will also be carried out manually with a hand sprayer, or it may be dispensed routinely to reduce exertions. The learn about performed in northern Missouri used soybean oil and an automated supply gadget.

The sprinkling gadget examined in a northern Missouri swine completing barn lowered PM10 emissions by means of 62-74 p.c and TSP emissions by means of 38 to 62 p.c relative to an adjoining barn with out oil sprinkling. An identical discounts in TSP emissions were seen in earlier research the usage of more than a few strategies of oil utility.

Within the Missouri learn about, ammonia emission charges have been lowered by means of 19 p.c, comparable to previous research that confirmed a 30 p.c aid in ammonia the usage of canola oil. The Missouri learn about confirmed a discount of 40 to 43 p.c in nonmethane hydrocarbons, even though there are not any different research to which those effects will also be in comparison. The Missouri gadget, the usage of soybean oil, had no important impact on emissions of hydrogen sulfide (H2S). Even if different research have reported no aid of hydrogen sulfide with oil sprinkling, research with canola oil have proven a 27 p.c aid in H2S emissions.

A discount of scent was once anticipated from the handled barn within the Missouri learn about as a result of particulate topic is a provider of scent. Then again, the scent aid seen from the oil sprinkling gadget was once inconsistent. On some sampling days, scent emissions from the oil sprinkling construction have been less than the regulate, whilst on different days, particularly towards the top of the trial, the oil sprinkling construction had upper scent emissions. This means that the oil residue might turn out to be an scent supply inside the barn throughout the latter duration of a cycle of pigs.

Oil sprinkling didn’t impact the offensiveness (hedonic tone) of the scent emissions. In different phrases, the scent from the construction receiving oil sprinkling within the Missouri learn about was once judged by means of an olfactometry (scent research) panel to be as unsightly because the scent from the regulate construction throughout some sampling occasions.

How, the place and when to sprinkle oil

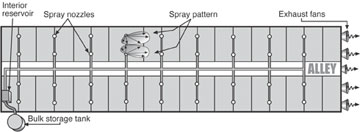

Soybean oil will also be saved in a bulk garage tank both inside of or out of doors the manufacturing construction and transferred to a smaller reservoir (Determine 1) within the construction as wanted. A mesh display screen will have to be added at the inlet to give protection to the nozzles from overseas subject material that might clog them. Oil can then be pumped with a water pump and motor (1/2 hp) this is both managed by means of a timer or is manually switched off and on day-to-day. The working drive of the gadget will have to be maintained between 40 and 60 kilos in line with sq. inch.

A easy supply gadget (Determine 2) can include 1-inch PVC supply line piping connected to the ceiling of the barn. A chief supply line will also be positioned down the middle of the construction with an acceptable choice of smaller supply traces branching out towards the sidewalls of the barn, in each instructions, at roughly 16-foot durations.

Each and every department will have to be supplied with fan-spray nozzles positioned roughly 1.5 ft from the aspect of the barn and roughly 1.5 ft from the middle alley (Determine 3). Relying at the period of the pens, further or fewer nozzles could also be wanted to offer good enough spray protection. As an example, one nozzle might supply good enough protection for 2 pens if positioned halfway between the alley and the wall.

The nozzles will have to be positioned no less than 10 inches from the roof and orientated to distribute the oil in a fan-shaped utility house. With tunnel air flow, the spray development will likely be slightly skewed because of air glide. This configuration will permit every nozzle to use oil to a couple of pens, essentially within the snoozing/laying spaces of the pen. This may occasionally adsorb mud debris in those spaces and make allowance the pigs to distribute the oil all through the remainder of the pen with their actions.

Oil utility will have to be have shyed away from in 3 distinct spaces of the barn:

- Pens close to the lovers

- Spaces adjoining to warmers

- Spaces surrounding feeders

Keeping off pens positioned close to the lovers will assist cut back the possibility of oil getting into touch with the louvers and the lovers. Over the top oil on those surfaces may end up in “caking” of mud and will impair fan and louver efficiency. Oil will have to now not carried out in spaces adjoining to gas-fired warmers as a result of this will likely constitute a hearth danger. Oil additionally will have to now not be carried out to the feeders as a result of oil utility can harden the feed. This hardened feed and oil residue calls for considerable effort to take away from the feeders, is unpalatable to the hogs and will create fly breeding habitat.

All through the primary day or two of a manufacturing cycle, soybean oil will have to be carried out at an preliminary fee of about 40 milliliters in line with sq. meter in line with day (mL/m2-day) for a start-up section. All through the rest of the manufacturing cycle, oil will also be carried out at a upkeep fee of five milliliters in line with sq. meter in line with day. In response to an approximate supply fee of four liters in line with minute, the oil sprinkling gadget will have to be operated for roughly 8 mins throughout every start-up day, and for one minute throughout upkeep days. It can be recommended to use the oil (whether or not manually or set by means of a timer) on the finish of the workday in order that the appliance will also be seen however slippery flooring have shyed away from throughout the everyday paintings duration.

Even if now not used throughout the learn about in northern Missouri, water or a surfactant or emulsifier will also be added to the oil for higher distribution and comfort of cleansing the barn between teams of pigs and for decreasing the prevalence of clogged nozzles.

In a Minnesota learn about, an injection pump (SHURflo 8000 style 4UN55) was once suited to an present water sprinkling presoak gadget to inject oil into the water line throughout operation. A Dayton general-purpose solenoid was once put in to turn on the glide of water. The hole of the solenoid and the operation of the injection pump have been managed by means of a timer (Intermatic ET100C). With a gadget the usage of a water/oil combination, the distribution gadget will also be flushed with water after the day-to-day oil supply to reduce nozzle clogging. Within the Minnesota learn about, the timer controlling the injection pump and solenoid was once set to perform for 2 mins. An period extend timer (Dayton, 6X604) was once used to close off the injection pump, preventing supply of the oil after one minute, whilst water persevered to run for any other minute.

A surfactant was once extensively utilized within the Minnesota learn about to cut back nozzle clogging. The surfactant (Alkamuls 600-DO, produced by means of Rhodia, Inc.) was once added to the oil at a 5 p.c answer fee by means of quantity (3 gallons of surfactant in line with 55 gallons of oil) to improve blending of the oil with water. The similar learn about extensively utilized an Aqua-Natural water filter out (style AP11T) to forestall nozzles from plugging because of mineral debris within the water.

Demanding situations with oil sprinkling

Because the temperature out of doors the confinement construction decreases, it turns into extra necessary to deal with the temperature of the oil inside the construction at an acceptable degree for utility. The oil will have to both be saved indoors, or heated if saved outdoor, to strengthen the glide of the oil when it enters the distribution gadget.

The commonest worry with oil sprinkling is the advent of slippery stipulations at the flooring, which can lead to a security danger for manufacturing staff throughout day-to-day paintings actions, particularly whilst making an attempt to take away pigs from the constructions. Sadly, this protection factor is inherent in an oil sprinkling gadget and will also be minimized however now not totally have shyed away from. Merely said, the oil can paintings to cut back mud technology provided that the oil coats surfaces (together with the flooring) within the constructions. Which means that any vegetable oil sprinkling gadget this is positive at decreasing mud may also create a security danger.

For the reason that oil sprinkling gadget creates an oily coating on surfaces to adsorb mud debris, cleanup of barns will also be anticipated to take longer (even with surfactants in waterborne techniques) than cleanup of barns with out sprinkling techniques. On a tunnel air flow gadget, fan louvers caked with oil and mud can turn out to be caught within the closed place. Further cleansing and upkeep are in most cases had to carrier the louvers on account of oil and mud adhering to the blades, and cleansing the barns between turns of pigs is perhaps extra time eating with an oil sprinkling gadget in operation. A degreaser is really helpful within the energy washing machine answer.

Value research

In response to the learn about performed in Missouri, it’s estimated {that a} sprinkling gadget will also be put in for roughly $2,100 in fabrics in a barn that comprises 1,100 hogs. This estimate comprises the price of pump, motor, timer, PVC piping and connections, and the nozzles, strainers and take a look at valves. Set up of the gadget calls for about 12 hours of work in line with barn. Annual prices for operation and upkeep for an 1,100-head barn are anticipated to overall about $1,100. Operational prices for oil sprinkling consist essentially of the oil itself, at a value of $3 in line with gallon. The velocity of oil use for an 1,100-head barn is ready a gallon an afternoon.

If a surfactant or water is added to the oil sprinkling gadget, further prices will observe. An injection pump (roughly $104), two timers (roughly $60 every) and a solenoid (roughly $100) will likely be required. To succeed in a 5 p.c answer, 3 gallons of surfactant will want to be added to every 55-gallon drum of oil, at a value of about $17 in line with gallon of surfactant.

Energy intake is minimum since the gadget simplest operates for one to 2 mins in line with day. As well as, minimum exertions is had to trade the oil provide steadily and to scrub and service nozzles.

The questions of safety and cleansing time can upload to the price of the gadget. Even if those prices are harder to quantify than the direct prices mentioned above, they can’t be omitted when comparing the full charge of an oil sprinkling gadget.

Additional knowledge

Well being results

- Donham, Ok.J., D. C. Zavala, J.A. Service provider. 1984. Respiration signs and lung serve as amongst employees in swine confinement constructions: A cross-sectional epidemiological learn about. Arch. Environ. Well being 39:96–101.

Odors and gases

- Ni, J.Q., A.J. Heber, T.T. Lim, C. Diehl, R. Duggirala, B. Haymore, and A. Sutton. 2000. NH3 emission from a big mechanically-ventilated swine construction throughout heat climate. J. Env. Qual. 29:751–758.

- Ni, J.Q., A.J. Heber, C.A. Diehl, T.T. Lim, R.Ok. Duggirala, B.L. Haymore. 2002. Traits of H2S concentrations in two robotically ventilated swine constructions. Can. Agric. Eng. 44:11–19.

Machine design

- Pasnek, D.A., L.D. Jacobson, V.J. Johnson, and R.E. Nicolai. 2001. Design and control of an oil sprinkling gadget to regulate mud, scent, and gases in and from a curtain-sided pig completing barn. Convention Complaints 2001 ASAE Annual World Assembly, Sacramento, Calif., July 30 to Aug. 1, 2001.

- Zhang, Y. 1997. Sprinkling oil to cut back mud, gases, and scent in swine constructions. Midwest Plan Provider E-newsletter AED42.