The COVID-19 pandemic used to be a difficult time for a large number of other people, together with companies. The location used to be bleak at Chikkamagaluru too, at BG Boutique Paper Turbines Personal Restricted. BG Seetharaman, Founder and Managing Director of the corporate, confronted a difficult time in maintaining the hand-crafted paper corporate working.

Captivated with sustainability and combating agricultural and plastic waste from getting into the landfills, he used the time to brainstorm concepts to paintings on his dream challenge which used to be an-end-to-end answer that may save you cast wastes from getting into landfills. However how may that be achieved? Through growing a gadget that recycles waste at supply.

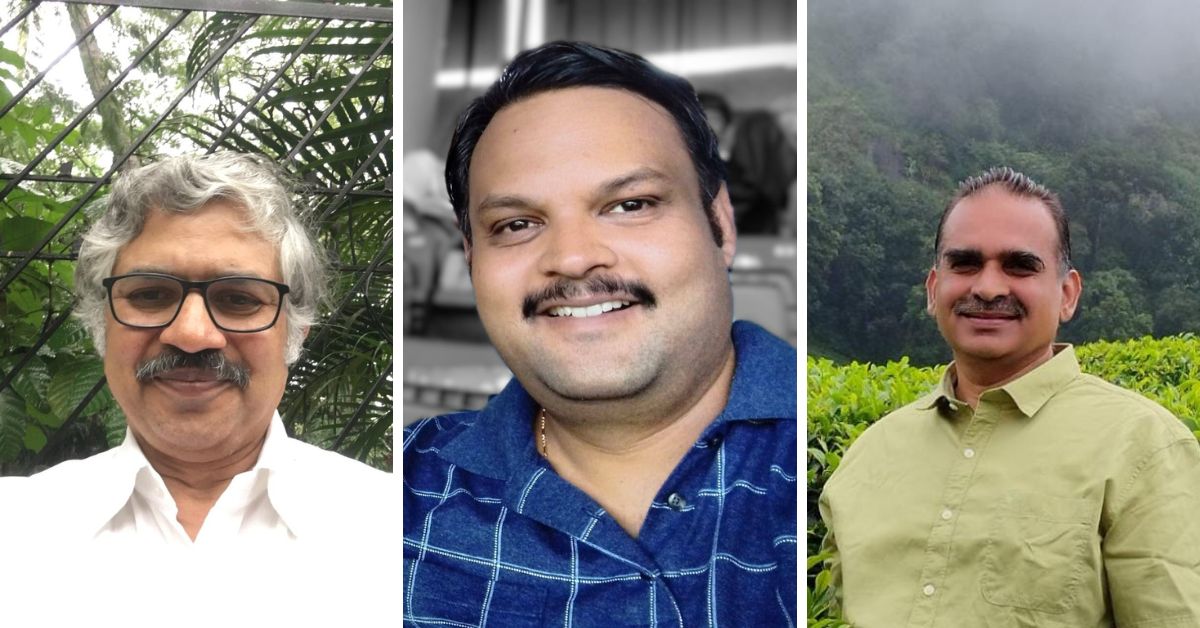

He mentioned this concept with Vinay Kumar, a social entrepreneur, and Rajeeva Deekshit, a inexperienced chemical skilled, over the following few months. They got here to a conclusion that the 2 spaces they sought after to focus on have been waste paper and fibrous agricultural waste.

The issue, in step with the founders is that, about 30,000 tonnes of paper is entering the landfills because of being lined with plastic or aluminium and are infected with drinks that makes it wrong for recycling. However, virtually 87 million tonnes of crop residue is burned yearly in India, as in keeping with a Science Direct document.

To stop this, the trio began Indic Tasks in July 2022 and feature evolved a considered one of its sort waste paper recycler that tackles the tricky to recycle paper cups, label free up paper, tissue papers and tetrapaks. Their gadget recycles this waste into pulp forums, which may also be additional used to fabricate paper and moulded merchandise.

Incubated at NSRCEL (IIM Bangalore) and IIMV FIELD (IIM Visakhapatnam), the startup is making plans to patent the gadget’s design and procedure.

Tackling the tricky to recycle plastics

A mechanical engineer from BITS Pilani, Seetharaman additionally pursued analysis on the Indian Institute of Science in Bengaluru. After operating at Seshasayee Paper and Forums for a couple of years, he arrange his personal hand-crafted paper unit in 1997, referred to as BG Boutique Paper Turbines.

Right here, he claims that they make 100% recycled paper, paper luggage and stationery from jute and cotton waste.

“We constructed a semi-automatic gadget in 2014 as a ready-made paper gadget used to be no longer to be had to our dimension, to procedure say 100-200 kg in keeping with day. We designed it to make paper from uncooked fabrics like jute waste, leather-based waste, banana waste and different distinctive uncooked fabrics,” Seetharaman stocks with The Higher India.

Since the price of manufacturing used to be excessive, the primary lockdown in 2020 brought about an enormous roadblock. Now, the engineer and scientist considered growing a whole product which might recycle paper waste at supply. He calls it an ‘end-to-end paper gadget’.

The problem lay in construction generation which might get better blank plastic, through eliminating silicone coatings, hazardous elements and beverage stains.

Seetharaman had already labored with Rajeeva in 2017 to create a generation that got rid of glassine from label free up papers.Their generation may recycle this silicone lined paper.

“Label free up papers have a silicone coating which is hazardous and no longer recyclable. A large producer had approached us to broaden a generation to take away the coating and get better pulp. I knew that lets use the similar generation for paper cups and tetra packs too,” provides Seetharaman.

Tetra packs too come lined with plastic or aluminium and are typically infected with drinks, tissue paper, and label free up paper. Because of those headaches, tetra packs and paper cups don’t seem to be typically recycled, opines Seetharaman.

“We discovered that they’re getting recycled successfully on account of their layers of plastic and aluminium. Separation of those layers isn’t achieved,” he provides.

Due to grants and awards after profitable ELEVATE Karnataka 2023 and Nidhi Prayas 2023, they constructed a pilot plant in Chikkamagaluru, the place they have been in a position to successfully separate plastic from the paper cups and silicone gum from silicone lined paper.

As of late, they’ve an evidence of thought on the minimal viable product capability.

“Our unit can get better blank plastic and aluminium coatings for reuse, get better hazardous ink waste for reuse and upcycled fibrous agricultural wastes to create paper pulp that may be made into high-strength paper used for packaging,” says Vinay, Founding father of Indic Tasks.

A chartered accountant through schooling, Vinay is a social entrepreneur based totally in Bengaluru who began Indic to offer a platform for indigenous inventions that may receive advantages the rustic.

How the gadget works

“As soon as the paper cups, tetra packs or tissues are won, they’re manually put throughout the recycling gadget. The elements undergo a three-stage procedure. With regards to tetra packs, the gadget makes use of a chemical suspension to split it into aluminium, plastic and pulp. With regards to paper cups, it’s separated into plastic and pulp. The pulp is then transformed into pulp forums,” says Seetharaman.

Those pulp forums are bought as uncooked fabrics for paper making or making moulded merchandise. The aluminium and paper waste is taken care of one by one and given to recyclers.

Rajeeva states that they evolved an eco-friendly answer which separates those aluminium, silicone and plastic from tetra packs and paper cups respectively.

Every other distinctive facet concerning the gadget, says Seetharaman, is that there will probably be no effluents launched through the machines.

“Each within the paper and agriculture machines, now we have ensured that there’s no effluent launched. Even in relation to banana waste, we’re having a look at extracting the sap and the use of it as a liquid fertiliser. It’s going to be a nil liquid discharge association,” he provides.

Their gadget is designed for villages, department stores, airports and extra. It comes with a capability of recycling 50 kg of paper waste in keeping with day, which may also be prolonged to 150 kg. A bigger gadget which will procedure as much as one tonne could also be to be had.

Recently, they’re in talks with some village panchayats and department stores in Karnataka and hope to release quickly.

“Transportation of paper waste for recycling to greater crops is tricky and typically doesn’t occur. To stop this, we will have to supply choices to recycle at supply. We wish to make sure that all waste generated is transformed to just right high quality pulp forums. We can facilitate a buyback fashion for the pulp and ship it to a paper mill or moulded product unit to near the loop,” provides Seetharaman.

The function is to make sure that each piece of waste, be it plastic or paper, is no longer despatched to the landfills.

Edited through Padmashree Pande, Photographs Courtesy BG Seetharaman