Be informed extra about checking your apparatus forward of chick placement

Editor’s observe: This newsletter is an excerpt from the Cobb Breeder Control Information and extra articles will observe. The Information used to be designed to focus on essential elements which can be possibly to steer flock efficiency. To learn or obtain the entire Information or to view Cobb’s different control guides, click on right here.

Sooner than hanging chicks, the apparatus and surroundings will have to be completely assessed and changed as wanted. Underneath are some pointers.

Minimal air flow assessments

- Minimal air flow will have to be activated as quickly because the preheating starts, to take away waste gases and any extra moisture.

- Seal air leaks to get rid of drafts on chicks.

- Test carbon dioxide stage ahead of hanging chicks. CO2 ranges will have to at all times be <3000 ppm.

- If chemical substances are used all through the cleansing and disinfection segment previous to chick placement, ok air flow will have to be used to transparent the home of the residue and to offer clear air for the chicks.

Ambient air temperature assessments

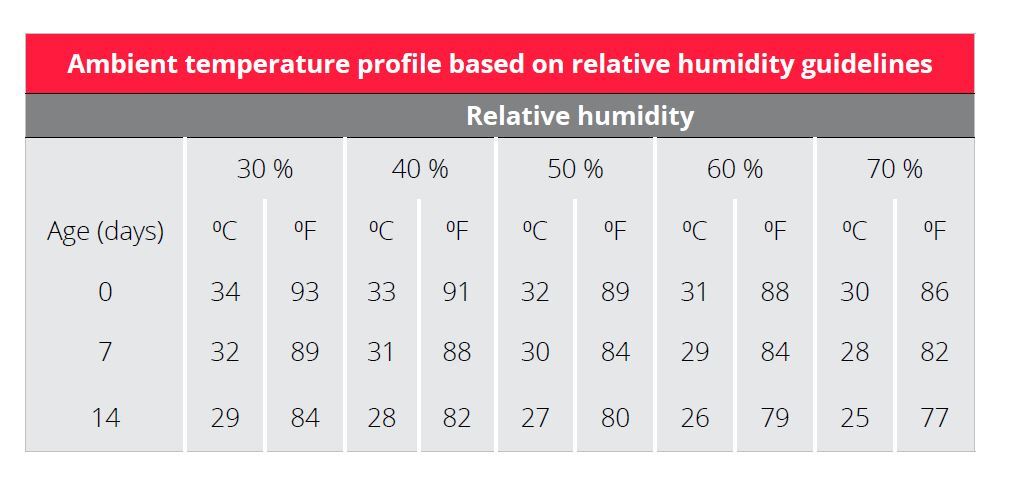

Temperature sensation is suffering from temperature switch and relative humidity of the air. If air is dry with low RH % switch is low and better dry bulb temperatures will have to be used as illustrated within the desk to the appropriate.

Heater assessments

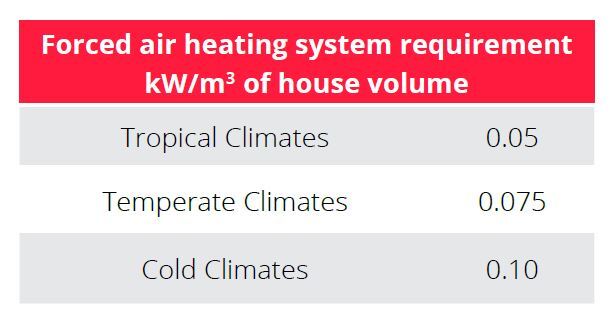

The important thing to maximizing chicken efficiency and welfare results is offering a constant housing surroundings optimized for the wishes of the birds. That is particularly essential for younger birds the place a constant ambient and flooring temperature are essential to advertise excellent task and customary habits. The heating capability requirement will depend on ambient temperature, roof insulation and area sealing. Check that each one warmers are put in on the really helpful top and are running at most output. Warmers will have to be checked and serviced BEFORE preheating starts.

Usually radiant brooders used together with compelled air warmers are the best. Radiant brooders are used as a number one warmth supply all through brooding whilst compelled air warmers supply supplemental warmth in chilly climate.

Because the flock matures, birds expand the facility to control their interior frame temperature. At roughly 14 days of age, compelled air warmers can develop into the principle warmth supply, however will have to handiest be utilized in smartly insulated cast wall properties. Radiant sort warmers will have to be used as the principle warmth supply in poorly insulated properties.

Radiant / Spot brooders

Both conventional pancake brooders or radiant brooder methods are used to create flooring and muddle heating patterns inside of the home. Those methods permit the chicks to transport across the brood chamber and to find their convenience zone. There will have to be some to be had water and feed just about this warmth supply.

Beneath flooring heating

The program operates with scorching water circulating thru pipes in a concrete flooring. The warmth trade inside the flooring warms the muddle and the brooding house.

Compelled air warmers

Those warmers want to be positioned the place the air motion is gradual sufficient to permit optimal heating of the air, typically in the midst of the home. Those warmers will have to be positioned at a top of one.4 to one.5 m (4 1/2 to five toes) from the ground – a top that won’t reason drafts at the chicks. Compelled air warmers will have to by no means be positioned close to the air inlet as a result of it’s unattainable for them to warmth air this is transferring very rapid. Warmers positioned on the inlets will result in an building up in power utilization and price.

Flooring temperature assessments

Regularly concrete/muddle temperature is measured briefly at chick placement in a couple of random spaces, which isn’t consultant of the actual uniformity of concrete/muddle temperatures. The most productive method is to measure (each concrete/muddle) each and every 6 meters (20 toes) alongside the period of the poultry area and in 3 rows around the width of the home. This will likely assist determine scorching or chilly zones in the home previous to chick placement. The muddle temperature will have to be recorded ahead of every placement. This will likely assist to guage the preheating effectiveness and make any essential changes for long run placements.

- Homes will have to be preheated in order that each the ground and ambient temperatures and humidity are stabilized a minimum of 24 hours ahead of placement.

- To reach the above goals, preheating must start a minimum of 48 hours ahead of chick placement.

- Preheating time relies on local weather stipulations, area insulation and heating capability and can range from farm to farm.

- Concrete temperature (underneath muddle) will have to be 28 to 30°C (82.4 to 86.0°F). Concrete temperature will have to by no means exceed 32°C (90°F).

- At placement, muddle temperatures will have to be 30 to 32°C (86 to 90°F) with compelled air heating.

- If radiant heater/brooder stoves are used, flooring temperatures will have to be 40.5°C (105 °F) beneath the warmth supply.

- Flooring temperatures will have to be 30 to a most of 32°C (86 to 90⁰F) when checked a minimum of 1 m (3 toes) clear of the middle of the radiant heater or brooder range. Above 32°C (90⁰F ) feed consumption decreases, and at 35 °C (95 °F) stops altogether.

- The variation between the temperature (at chick stage) in the back and front of the reception house will have to no longer exceed 0.20ºC (0.36ºF). Uniform temperatures can also be accomplished the usage of recirculation enthusiasts to combine the air continuously.

Thermostats or temperature probe assessments

- Positioned at chicken top and lightly allotted round the home. Don’t position without delay beneath the heating supply.

- Thermostats and temperature probes will have to be calibrated a minimum of every year, or faster if doubt exists about accuracy.

- Minimal/most thermometers will have to be positioned adjoining to thermostat.

- Temperature levels will have to be recorded day by day and no longer deviate via greater than 2°C (4°F) over a 24-hour length.

Drinker assessments

- For partial area brooding, permit 40 chicks consistent with nipple. When the home is absolutely opened, permit 8 to ten birds consistent with nipple.

- For bell drinkers, permit 75 birds consistent with drinker. For some bell drinker designs, the lip of the drinker is also too prime and the chicks won’t be able to achieve the water. On this case, supplementary drinkers will likely be essential.

- Flush all drinkers to take away any residual sanitizer. Water will have to be clear and contemporary.

- Modify force to provide a droplet of water visual on every nipple, with out dripping. Test for any explicit suggestions from the producer for force settings.

- Test for water leaks and air locks.

- Make sure that nipple drinkers are on the chicks’ eye stage at reception. Modify traces after 2 days so the chicks’ necks are relatively stretched to drink.

- If wanted, provide 1 supplementary drinker (3.8 L, 1 gal) consistent with 100 chicks. Supplemental drinkers will have to be positioned relatively upper than the muddle to deal with water high quality however no longer so prime that get right of entry to is impeded. For instance, on best of a field lid or egg flat. They will have to even be positioned just about the principle supply.

- Behavior water bacteriological research ahead of chick placement to evaluate the standard of the cleansing and disinfection procedure. Test the sanitizer focus on the finish of the loops day by day.

Feeder assessments

- Run the feeding gadget previous to chick placement to come across any minor issues and right kind any problems.

- Test feed distribution traces to verify they’re stage and secured.

- For chain feeder methods, lubricate the gadget consistent with producer’s directions. Test the chain stress and scan the road for overseas items that may develop into lodged and harm the gadget.

- Make sure that feed hoppers are clear, dry and able to be stuffed.

- Feeders will have to be adjusted for chick top. First of all, feeders (pan and chain) will have to be at floor stage so the chicks can simply get right of entry to them.

- Calibrate the scales used to weigh the feed previous to the flock placement. Correct weighing of feed is significant to stop over or beneath feeding the flock.

Repairs

Apparatus screw ups can also be devastating and lead to huge losses. A complete farm plan will have to come with common, scheduled and preventative upkeep to stop apparatus screw ups. Alternative and spare portions will have to be to be had at every farm to stop delays in upkeep. An on-site, written logbook will have to be used to report common

assessments (ex: generator trying out), regimen on-site upkeep, and primary upkeep issues that want to be scheduled.

Main upkeep and mechanical upkeep will have to be achieved between flocks and together with cleansing to attenuate biosecurity possibility at the farm. Pre-placement

upkeep assessments are crucial and will assist ensure that the hen area is able to safely and very easily area new birds. Create a written plan and tick list of

spaces and pieces that will have to be verified for upkeep ahead of housing a brand new flock. Examples of things to incorporate:

- Feed – test feed scales and calibrate weighing apparatus to stop

over/under-feeding. Per 30 days calibration of feed scales is a great observe.

Check the clean-out procedure for feed containers to make certain that apparatus is

clear and dry previous to receiving new feed. - Feed supply methods – test augers, chains and feeder setup to

make certain that the gadget will paintings to ship feed to the birds and to verify

it’s protected and won’t lead to chicken harm. - Water – test water traces and particular person drinker nipples for water. Flush

the water gadget to verify all cleansing and disinfecting answers have

been cleared from the traces. - Air flow – test fan belts, fan motors, louvers, fuel traces for warmers, and many others.

to verify they’ll paintings appropriately to deal with the suitable temperature

for chicken convenience. Ventilate the home previous to receiving birds to take away

chemical odors from the cleansing and disinfection procedure. Calibrate

sensors and thermometers to verify controller settings will likely be correct. - Area construction – cycle (test) all curtains and vent doorways to verify

cables don’t seem to be tangled or damaged which might affect the effectiveness of

the air flow apparatus. - Area apparatus – exchange any damaged or flickering gentle bulbs in the home, check security and safety of any dividers or different chicken apparatus (ex: slats, nests, catch frames, scales, and many others.) in order that any upkeep can also be made previous to flock arrival.

- Emergency apparatus – check the generator to make certain that it’s operating appropriately to offer instant backup energy for the farm all through an emergency. Turbines will have to cycle beneath load as soon as monthly to ensure that they’re operational. Have an electrician or generator specialist behavior an annual assessment of the generator. Check the alarms, alarm gadget, and many others. to make sure that audible alarms are purposeful and radio/computerized alarms touch the right kind individual(s) for an emergency.

- Exterior surroundings – visually check the stipulations of the home (ex: cool mobile pads, safety of doorways and drainage apparatus, safety of perimeter fence, crops and vermin regulate bins, and many others.) to make certain that biosecurity and premise safety are purposeful.

Alarms and emergency making plans

Problems might stand up that require emergency responses. Minor occasions (energy or apparatus screw ups) and primary occasions (serious climate, flooding, wind harm) can happen that may reason harm to housing and prohibit or save you get right of entry to to essential assets together with feed and water.

At least, breeder operations will have to have a written plan for emergency responses that incorporates usual running procedures (SOPs) to evaluate and restore structural harm, lack of energy, lack of water, notifiable illness presence (at the farm or within the regional house), catastrophic problems inflicting the shortcoming to ship feed, and emergency depopulation.

Alarm methods will have to be used to continuously observe the hen area surroundings and housing methods (temperature, water availability, electrical energy, and many others.) which can be essential to provide the day by day wishes of the flock. Preferably, backup methods comparable to turbines for electrical energy and a secondary water provide will have to be provide on-site and will have to be often monitored. Touch data for emergency reaction services and products and body of workers liable for addressing emergencies will have to be posted in a spot the place the tips is definitely available.