With the want to organize and measure emissions rising in significance, HELEN BROTHWELL appears to be like at how present and long term choices to mitigate ammonia emissions on UK farms can paintings in follow, together with the wide-ranging PigProGrAm venture and different slurry control applied sciences that may deliver further productiveness and monetary advantages, in addition to decreasing emissions

Figuring out find out how to organize and measure environmental emissions and pollution, specifically ammonia, carbon, nitrogen and phosphorus, will simplest build up in significance for all pig manufacturers as we transfer thru 2024.

Many gadgets are already working beneath the Environmental Allowing Laws (EPR), which these days contains automatically reporting ammonia emissions to the Atmosphere Company (EA), operating in opposition to the nationwide goal of decreasing ammonia emissions by way of 16% by way of 2030.

EPR adjustments from 2024

The EA has equipped an replace on imminent adjustments to EPR necessities in 2024 and past:

Ammonia emission issue evaluation: The EA commissioned an exterior venture to tell and proof updates to its usual ammonia emission elements, which approved gadgets use to calculate emissions. The file has now been finalised and there will likely be a brief evaluation and inside session duration earlier than the up to date suite of emission elements is revealed.

Local weather alternate adaptation: The brand new requirement is for all approved farms to provide a local weather alternate possibility review by way of March 31, 2024. The EA is encouraging operators to provide this review over the following few months. There’s a possibility review template, together with hyperlinks to EA steering, at the AHDB web site.

N and P reporting: This reporting requirement will likely be prolonged to all approved farms with retrospective reporting for the 2024 calendar yr being required from January 2025. Thereafter, this will likely be an annual reporting requirement.

The EA will in a while free up main points of a brand new mass steadiness calculator software and supporting knowledge to lend a hand farmers to file annual cattle N & P excretion ranges. Manufacturers can both use the brand new mass steadiness software or file excretions the usage of result of slurry/manure sampling. The reporting gear for pigs and poultry will likely be at the AHDB web site in 2024.

The exceptions to this are farms within the Wye catchment (all poultry), which can, once more, be required to file annual cattle N & P excretions by way of February 29, 2024.

Templates and extra main points on find out how to conform to EPR are to be had at: https://ahdb.org.united kingdom/knowledge-library/environmental-permitting-regulations.

Slurry garage and control

For all farms, now not simply approved ones, the federal government’s Blank Air Technique 2019 states that every one slurry and digestate shops in England should be lined by way of 2027.

The slurry infrastructure grant scheme, detailed within the November version of Pig Global, is open to packages from pig manufacturers. AHDB’s slurry wizard software will lend a hand manufacturers calculate slurry garage necessities to conform to laws.

In addition to masking slurry shops, the usage of gentle slurry acidification is these days the one different choice slurry control methodology formally recognised by way of the EA and different govt companies, Zanita Markham, AHDB initiatives and engagement dating supervisor defined.

“Slurry cooling could also be fashionable and will cut back carbon footprint by means of power saving,” she mentioned.

“Acidification and cooling each cut back emissions ‘at supply’, which additionally deliver advantages for the surroundings within the development, and various industrial farms in the United Kingdom have invested in those lately.”

Slurry control applied sciences like this may deliver further productiveness or monetary advantages, in addition to cut back emissions.

Farm case learn about: Slurry acifification

Lincolnshire Beef Co, winner of the Sustainable Farming Award on the 2023 Nationwide Pig Awards, runs a farrow-finish trade, with two 750-sow breeding gadgets, which rear pigs to 35kg, earlier than shifting them to deep-straw completing websites.

To lend a hand fortify the surroundings within the constructions for each pigs and stockpeople and cut back ammonia emissions, they integrated a slurry flushing and acidification device in a rebuild in their farrowing and nursery lodging on each breeding gadgets remaining yr.

“It’s a part of our purpose to create a round farming device, decreasing ammonia emissions from pig manufacturing – within the pig area, the slurry retailer and within the box, in addition to making higher use of vitamins within the slurry implemented to arable vegetation,” mentioned Lincolnshire Beef Co’s Sam Ward.

The trade used JHAgro/Agremeica to put in the device, taking self assurance from the company’s vast enjoy in Denmark.

Gentle acidification of slurry brings its pH right down to not up to 6, which means ammonia is transformed to ammonium which doesn’t evaporate. Acidification programs can cut back ammonia emissions by way of as much as 67%.

Slurry from the pig housing is frequently got rid of from the shed by means of pipework to a processing tank, the place small quantities of sulphuric acid are routinely added, in keeping with pH sensor readings.

Nearly all of the acidified slurry strikes to a garage tank, with some biking again spherical to the pig housing to begin a light acidification procedure within the housing when dung drops in the course of the slats into the slurry.

“Ammonia screens have been fitted and connected to BarnReport Professional and confirmed a discount in ammonia from 40ppm to 4ppm,” Sam defined. “There also are advantages for pig well being, enlargement charges and decreased mortality. Even if it’s hward to measure those and to mention how a lot is right down to slurry acidification, nursery mortalities are down to at least one.6% and 1.7% at the gadgets.”

Many of the get advantages is noticed at the arable facet of the trade, with vitamins in each the slurry and soil changing into extra to be had to the farm’s vegetation.

“Acidification will increase the ammonium within the slurry, which isn’t as volatised as ammonia,” Sam added. “Additionally, the farm is on limestone soils which can be pH 8, with out a lime implemented, and those prime pH soils can lock up vital crop vitamins, phosphate and magnesium.

“Making use of the acidified slurry at the arable fields acidifies the foundation zone, making the vitamins within the soil extra to be had to the arable vegetation, in addition to expanding availability of vitamins within the slurry. It makes the device an ideal have compatibility.”

The corporate has additionally made important financial savings on sulphur fertiliser, displacing its sulphur necessities throughout its 1,100 hectares.

With team of workers retention an ongoing problem, Sam mentioned enabling team of workers to paintings on a contemporary unit in the most productive atmosphere conceivable used to be every other attention.

The nursery and farrowing homes have a really perfect environment within, with out a obtrusive scent of ammonia.

The primary operating prices are the electrical energy for pumping and combining, in conjunction with sulphuric acid to acidify the slurry.

Set up of slurry acidification programs can value upwards of £400,000, mentioned Zanita however grant investment is also an possibility. Prices have been much less when Lincolnshire Beef Co put in the device they usually bought 40% grant investment.

Farm case learn about: Slurry cooling

A North Yorkshire pig manufacturer with 2000 sows opted to place in a slurry cooling device two years in the past underneath new farrowing lodging for 280 sows, choosing era from Danish company Klimadan.

“We noticed there used to be possible for power financial savings in addition to relief in ammonia emissions,” the manufacturer defined. In accordance with Danish research, cooling has been proven to cut back ammonia emissions by way of as much as 75% and odours as much as 15%.

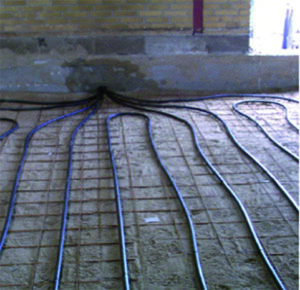

A circuit of pipework used to be put in within the concrete flooring of the under-slat slurry shops. The outside of the slurry available to buy is cooled to twelve°C or much less by way of pumping chilly water thru warmth alternate pumps and the warmth is reused to warmth lend a hand warmth the development.

“There’s a noticeable development within the scent within the constructions and with a bit of luck in long term we’ll be capable of supply figures on ammonia relief if the EA wishes them,” mentioned the manufacturer.

“Our two warmth alternate pumps are generating simply shy of 4kW for each and every 1kW of electrical used to energy them, and I’d estimate we’re getting round 2.5kW to in fact warmth the development, taking into consideration losses alongside the pipes.”

The device used to be put in simply in time to qualify for the Renewable Warmth Incentive, so that they obtain a fee for generating the warmth, despite the fact that that is now not to be had for brand spanking new warmth alternate programs.

On this case, two current biomass boilers at the unit give you the warmth for 200 farrowing puts within the development, with the cooling device heating the opposite 80 pens.

“This steadiness is solely right down to the RHI’s device which means that we’re these days financially to say nearly all of the RHI fee at the biomass,” the manufacturer defined.

“In the long run there may not be RHI on biomass, so we’ve got the warmth pumps in position as back-up, which they already supply if the biomass boilers move down.”

The unit additionally has sun panels to lend a hand energy the warmth pumps. The overall funding used to be £35,000, with the manufacturer offering their very own labour, however slurry cooling can value as much as £50,000.

“Be sure you handle an organization who will provide you with self assurance because it’s a large funding,” he steered. “We went with Klimadan who had numerous enjoy putting in the device on farms in Europe.”

There’s a elementary annual provider for the pumps and the one operating value is the electrical. “The producer’s anticipated lifespan is twenty years and I’d estimate we’d get a go back on funding in 3 years with the RHI, or 5 years with out,” mentioned the manufacturer. “We have been already the usage of the biomass boilers so there used to be no power saving however, when you have been shifting from electrical energy, the saving can be round £1000 per 30 days.”

They’re these days putting in every other cooling device in more farrowing lodging with 96 puts.

“Should you’re striking up a brand new development, I believe it’s price no less than laying the pipes for a cooling device within the ground, although you don’t put money into the warmth pumps till later,” the manufacturer mentioned.

Farm case learn about: Inexperienced gasoline from slurry

The PigProGrAm is a significant trial aiming to cut back ammonia emissions and discover the feasibility of the usage of the ammonia to provide hydrogen – a zero-carbon gasoline – to cut back the carbon footprint of pig manufacturing, along the usage of co-products in feed.

The venture’s complete identify is ‘Creating a Round Financial system for UK Pig Manufacturing Thru Inexperienced Ammonia Harvesting’ and it has gained £600,000 of investment beneath the Govt’s Farming Innovation Pathway collaboration between Defra and UKRI.

Supply companions come with AHDB, Beta Generation, Duynie Feed UK, the College of Leeds, Membracon and an indoor pig manufacturer.

“If ammonia from pig slurry can in the long run be transformed to ‘inexperienced’ hydrogen and used to gasoline tractors or vehicles, it adjustments from an environmental downside to an answer, which is able to lend a hand cut back carbon emissions in farming and past,” mentioned Zanita.

The primary apparatus within the trial, on a North Yorkshire finisher unit, is a downflow gasoline contactor (DGC), regularly utilized in water remedy vegetation. This releases the ammonia from the liquid fraction of the slurry and adjustments the ammonia from liquid to gasoline shape.

“We also are the usage of best possible follow slurry control tactics at the farm together with a pit recharge device and flushing and isolating the slurry each and every 48 hours,” Zanita defined.

There are 3 major spaces of knowledge assortment, with complete effects set to be revealed in Pig Global quickly:

1) Ranges of ammonia it’s conceivable to extract from the separated slurry by means of the DGC procedure.

2) Tracking of ammonia emissions leaving the shed.

3) A complete lifecycle research to measure relief in carbon footprint, taking into consideration co-product feed, animal efficiency and slurry control.

“The following level can be to analyze the possibility of hydrogen manufacturing thru electrolysis of the harvested ammonia, which is already a recognised procedure,” Zanita mentioned.

“If extra investment used to be granted, we might glance to check the ammonia-rich product on farm for its electrolysis possible