Biosecurity is a phrase we listen frequently in swine manufacturing however what does it in reality imply? After I consider an how to give an explanation for this subject to a feed mill, I generally tend to make use of the next: Biosecurity is a method to create sensible and science-based how one can scale back the possibility of viruses and micro organism coming into our manufacturing gadget.

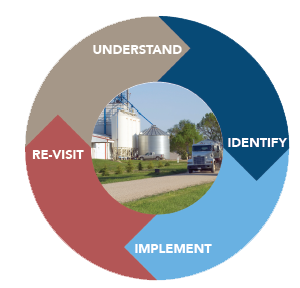

Traditionally, biosecurity has began on the farm stage through showering out and in of amenities, danish entries, filtering amenities, disinfection protocols, and quarantine for incoming gilts. Then again, when considering of the following stage of biosecurity, feed rises to the highest of the checklist as it’s the subsequent biggest amount product coming into into the farm. Biosecurity remains to be a difficult activity on the feed mill as they’re made up of complicated networks of other folks, processes, and components. Subsequently, it turns into vital for feed turbines to apply the continual cycle of working out, figuring out, enforcing, and revisiting.

Perceive the Chance of Feed

Because the advent of porcine epidemic diarrhea virus (PED) to the US, a considerable amount of analysis has been performed round the real possibility that feed carries in our manufacturing methods. This comprises components, procedure, apparatus, and team of workers. Every mill could be very other, however the processes and possibility are most often very identical. Despite the fact that feed is probably not the principle direction of transmission, and usually is reasonably small, the magnitude of an infection can also be excessive and purpose a big financial loss to a farm or gadget.

Figuring out Chance Elements The use of Audits & Science

One of the best ways to spot spaces of outrage in both an owned mill or toll mill is to first determine any attainable spaces a contaminate can input the manufacturing gadget. This can also be finished through making a float diagram for the feed mill record out each and every procedure and actions of other folks and vans. Generally, the main house of outrage comprises components, vans, and other folks. Then again, in some methods there might be further spaces of outrage similar to cattle shut through or on-site. Our solution to determine possibility elements has been to create an audit shape the use of the latest medical analysis that now not handiest ratings a feed mill however may even lend a hand the mill higher perceive the place the main possibility spaces inside of a feed mill can originate. This method permits for dialog and brainstorming to determine what procedures can also be installed position that aren’t handiest a success however sensible for the mill staff.

Enforce Methods

The #1 query that will get requested in regards to the implementation of a process or product is will or not it’s sensible? Two of essentially the most sensible and a success tactics that we have got applied within the feed business are truck washing and the usage of feed mitigants.

- Prevention Technique -Truck sanitation is likely one of the maximum necessary procedures to verify a bio-secure feed supply. In maximum circumstances that is finished with a pump sprayer the use of sanitizer and handiest comprises the tires and undercarriage. What we now have discovered from analysis over the last few years is that the cab of the truck is changing into an overly necessary a part of the sanitation procedure. The use of sanitizers which are used at the tires of the vans or in foot baths can be used within the cabs and at the flooring mats of the vans. Each strategies of washing the out of doors of the vans and sanitizing the cabs are very sensible and can also be finished on the finish of the feed supply direction or after visiting a website of outrage. Now not handiest does this give protection to the farms but it surely additionally protects drivers from sporting a possible contaminant again to the mill. This procedure can be performed on factor vans coming into a facility.

- Feed Mitigation -The second one method is the usage of merchandise that comprise acids, alkalis, very important oils, medium chain fatty acids, and formalin are residual mitigation gear. Those merchandise can give a long-lasting impact at the feed through which it might probably stay the product freed from pathogens after the feed is handled. This reduces the danger of components which may be infected and publish processing contamination/ recontamination.

During the last few years more than a few merchandise were examined amongst many viruses and micro organism which makes it crucial and tough to seek out the right kind form of product this is efficient in opposition to the pathogen of outrage. As an example a learn about printed in 2020 evaluated 19 merchandise in opposition to PEDV, PRRS, and SVA in feed. The result supplies readers with more than a few choices/sorts of merchandise that can be utilized to focus on 1, 2, or all 3 of the viruses. In case you have any questions relating to feed mitigation merchandise or the use of a feed mitigant, please achieve out to a member of Pipestone Vitamin or your veterinarian.

Revisit

After implementation it is very important revisit the procedures to verify they’re efficient and dealing correctly for the gadget. In some instances, you’ll have to exchange or adapt the procedures or audits to paintings in a selected gadget as each and every mill is other. Biosecurity will all the time be difficult and converting as extra information turns into to be had and new era is presented.

Every yr we proceed to make use of this information to enhance now not handiest our manufacturing gadget however to lend a hand different feed turbines enhance their biosecurity plans. Regardless of the method or pathogen of outrage we all the time proceed to make use of the continual cycle of biosecurity, which is to know, determine, put into effect, and revisit the use of a realistic and medical method.