Water is a huge determinant of the luck of a crop. However excess of simply availability, how water is implemented, when, and what sort of, is little short of a science. Irrigation professionals speak about how an irrigation device must be approached for absolute best effects.

Picture: Lindi Botha

With all farming operations, the important thing purpose is to beef up yields and high quality. That is accomplished via diet, water, genetics and local weather.

That specialize in water, a farmer’s selected irrigation device could make or smash his industry.

READ Making plans for precision irrigation

To get the most efficient from an funding in irrigation, a farmer must make certain that the precise device is carried out from the beginning, after which make certain that a right kind repairs programme is in position to stay this funding functioning optimally.

Hennie Needham, normal supervisor of Rivulis Irrigation in South Africa, says that there are six key issues farmers should be mindful when opting for an irrigation device: the kind of crop; the local weather; the sphere form and slope; the water supply and high quality; soil kind; and effort supply, availability and any obstacles with energy provide.

“As soon as these types of components are transparent, it’s going to be more uncomplicated to resolve the irrigation want, and due to this fact the scale and particular person parts required to irrigate optimally.”

With the crop kind in thoughts, your next step is to have a look at the local weather, and specifically the water required to develop the crop in that particular local weather. Needham explains that right here, precipitation, evaporation, temperature, and wind want to be taken under consideration.

“With the information of the precise crop you are going to develop, you want to resolve its water requirement, which is measured by means of evapotranspiration. This in flip, is decided by means of sun radiation, temperature, humidity, and wind.”

The evapotranspiration (ET) is the full amount of water this is utilized by the crop for transpiration, together with evaporation from the plant itself and moisture misplaced via evaporation from the soil floor.

The speed of evapotranspiration isn’t static. It fluctuates day-to-day, with traits throughout seasons. Sun radiation, temperature and wind velocity build up ET, whilst humidity decreases it.

A rule of thumb for the past due levels of vegetation is that the ET will usually be made up of 10% evaporation and 90% transpiration.

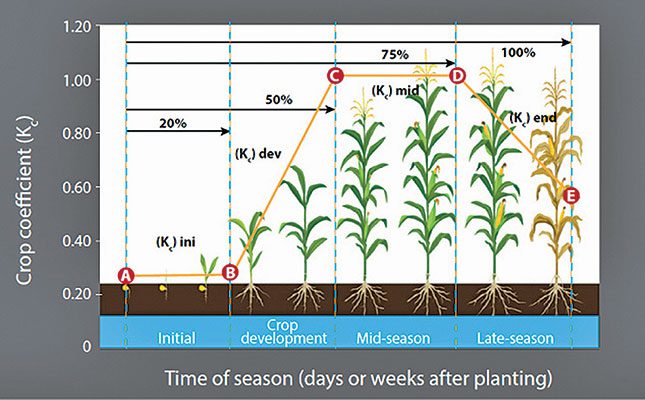

Typically, a standardised dimension for evapotranspiration fee (ETo) is used, which is in accordance with a reference crop of vegetative grass. The opposite part of the equation for plant water requirement is the crop coefficient (Kc).

It is a multiplier for a given crop used to are expecting water use at other expansion levels. Kc information is in accordance with a large number of years of crop analysis, however it must be tailored to the native selection and prerequisites.

There are a large number of assets of Kc to be had – on-line, or at crop trade our bodies, or seed firms.

To resolve the crop’s water requirement, take the ETo and multiply it by means of Kc.

An instance calculation will glance as follows: ETo for the day is 4,4mm. It’s mid-season, due to this fact the Kc is 1,15, and the sum appears to be like as follows: 4,4 x 1,15 = 5,06mm. The water requirement is due to this fact 5,06mm.

This quantity must on the other hand be seen with rainfall, and any precipitation should be taken under consideration to determine the full water availability, and what sort of irrigation is needed in a season.

As soon as this knowledge is established, it should be multiplied by means of the farm dimension to resolve the full water and irrigation requirement.

For the hydraulic design, on the other hand, the determine this is maximum necessary is the biggest irrigation quantity quantity within the season, as that is the quantity of water that the device wishes as a way to practice.

Figuring out water requirement

Needham notes {that a} not unusual mistake is the usage of reasonable water requirement as a information for an irrigation device.

READ Sensible irrigation saves water

“When you do that all through top water call for sessions, there’s a deficit of water, which results in yield relief, frequently on the most crucial time. The general irrigation design must be in accordance with the height water requirement, now not the typical water requirement.”

The lay of the land

Each and every farm is exclusive in its structure, and box and block configuration.

An irrigation device should due to this fact be designed with a selected farm in thoughts, and one design can’t essentially be copied and pasted for every other.

A topographical find out about of the farm will help in figuring out piping and distribution, distances from water supply and pump shed, and stress requirement.

The slope of the farm affects the kind of irrigation, since water stress will increase as elevations lower around the box.

Fastened pieces like box and repair roads should taken under consideration.

The following merchandise at the making plans tick list is soil kind. Sandy soils that leach simply require extra widespread periods, whilst clay soils want much less widespread periods.

Soil kind will even resolve whether or not you want to use water slowly to make sure soil infiltration and minimise run-off. Dripper spacing is decided by means of how the water will transfer laterally in the course of the soil because of the soil kind.

As soon as you’re armed with all this data, you’ll be able to way an irrigation corporate to come up with the most efficient resolution on your farm, making sure optimum yields and high quality.

Fertigation issues

Plant diet is likely one of the key spaces the place a large affect can also be made to extend luck in crop manufacturing.

Vegetation want vitamins to develop, battle off sicknesses and pests and reproduce, and the simpler provided they’re, the higher the yields.

Including a fertiliser part to irrigation is likely one of the absolute best techniques to make certain that crops get precisely what they want, when they want it.

Charl van Reenen, agronomy supervisor at Netafim South Africa, explains that precision fertigation is an optimum root-zone control instrument turning in simply the right mix of water and vitamins at once to the roots of every plant in line with crop phenological cycles.

“A hit plant diet is all about precise amounts, proper nutrient combos and exact timing. Through making use of diet in the course of the irrigation device and the usage of precision dosing generation to take action, you’ll be able to make certain that the proper amount and aggregate of vitamins is implemented precisely when the crop wishes it.”

Making plans and executing a fertigation plan and fertigation device calls for further analysis and session.

Vital knowledge all through the making plans procedure comprises fertiliser practices, reasonable yield, climatic and environmental stipulations, conventional nutrition-related demanding situations confronted, and the essential water and soil research knowledge.

The 3 maximum necessary construction blocks of a fertiliser plan are the nutrient wishes of the crop required to succeed in the manufacturing objectives, the specified fertilisers and amounts to succeed in the nutrient suggestions, and the applying approach.

It’s transparent that this side, too, calls for a tailored plan, and will’t be copied from every other farm.

Van Reenen says the preliminary price of enforcing fertigation is also excessive, however the praise outweighs the associated fee again and again.

READ Irrigation generation is making manufacturing inexpensive

“Rewards come with financial savings in fertiliser, labour and effort prices. Secondly, the rise in yield, because of optimised fertilisation, is frequently considerable.”

Those rewards are, after all, handiest yielded if fertigation is completed proper. Tracking all through the season and adjusting the fertigation movements in actual time is the overall key to greater luck.

Stay the device working

An irrigation device, like a tractor, calls for common servicing and upkeep to make sure it’s working in tip-top situation.

Since irrigation water is not likely to be completely transparent and with none soil debris, a filter out repairs programme is very important to stay the device working and save you huge blockages.

This sort of repairs plan leads to decrease total repairs price, diminished apparatus substitute prices, fewer interruptions to vital operations, progressed apparatus longevity, and greater potency.

Dexter Neethling, product supervisor for Netafim South Africa, relates that his staff frequently notices on farms that filter out repairs is overlooked, or completed incorrectly, which results in yield losses.

He advises farmers to divide repairs into 3 sections: weekly repairs, additionally repairs on the finish of the irrigation season, and that which is completed originally of the irrigation season.

“Visible inspection and checking out of parts is an integral a part of preventative repairs, be it examining filter out rings or checking the stress differential between the filter out inlet and outlet. This guarantees that conceivable issues are known and corrected sooner than they have got a vital affect at the potency and longevity of all of the irrigation device,” says Neethling.

Irrigation repairs steps

For display screen filter out repairs, weekly visible inspections want to be carried out on computerized, semi-automatic and handbook display screen filters.

The focal point must be on checking for leaks, which must be repaired once conceivable.

If there are not any leaks at the computerized display screen filter out, turn on a handbook flushing cycle to make sure the filter out is flushing effectively.

Your next step is to test the stress differential. If this price is abnormally excessive, carry out two extra handbook flushing cycles.

If the worth stays excessive after 3 handbook flushing cycles, the filter out must be opened, checked for failed portions and the display screen wiped clean manually if essential.

Practice the producers information

Make sure you practice the producer’s step by step information and all protection directions when opening the filter out and removing the display screen.

To scrub the got rid of display screen, use pressurised water to take away the remainder grime. Reinstall the blank display screen in line with the provider tips and practice all protection directions.

READ Is subsurface irrigation about to take off in South Africa?

In a semi-automatic display screen filter out, the cleansing operation should be initiated sooner than the stress differential reaches 0,5bar.

Some semi-automatic display screen filters have an automated clogging indicator that can keep up a correspondence when the stress differential prohibit is reached.

To start up the cleansing operation, open the drain valve and switch the care for the entire method out after which again in. The display screen’s internal can be wiped clean as you flip the care for and suction is created within the nozzles.

In case you are operating with deficient water high quality or low stress, you want to carry out the cleansing operation whilst the downstream valve is closed. Shut the drain valve after the method has been finished.

If the stress differential stays abnormally excessive after 3 finished cleansing operations, the filter out must be opened, checked for failed portions and the display screen wiped clean manually if essential.

In a handbook display screen filter out, a high-pressure differential will all the time require opening the filter out for handbook cleansing. Get started by means of ultimate the water provide to the filter out and opening the drain valve to unencumber the entire stress.

Open the filter out frame clamp and take away the filter out quilt. In moderation pull out the display screen part and blank it the usage of pressurised water.

If essential, use a cushy nylon brush for extra environment friendly cleansing. By no means use any abrasive gear and ensure the frame and display screen O-rings are lubricated sooner than reassembly.

Disc filters additionally require common repairs and must go through a normal inspection steadily. This must be completed sooner than any scheduled repairs procedures are performed.

Take a look at the stress differential between the filter out inlet and outlet, then start up a flushing cycle and recheck the stress differential a minute after the flushing cycle has been finished.

If the stress differential continues to be abnormally excessive, it is important to open the filter out and take away the discs for handbook cleansing. Prior to getting rid of the filter out quilt, shut the water provide to the filter out and open the drain valve to unencumber the entire stress.

Visually check up on the discs after they have got been got rid of. If there’s visual sediment, blank the discs in line with the provider’s suggestions.

Moreover, visually check up on the backbone and ensure the cone membrane isn’t broken. If any filter out portions are broken, change them right away.

When reassembling the backbone and discs, be sure that the choice of discs is proper as indicated by means of the road at the backbone, and lubricate the O-rings. Additionally, open the command filter out and blank its discs.

Neethling states that more than a few components resolve the luck of an irrigation device, of which filter out variety and set-up is however one side.

“To make certain that a filtration device assists in keeping functioning successfully and has a protracted lifetime, two components must by no means be overlooked: the usage of high quality merchandise, and device repairs.

The message is apparent: you can not come up with the money for to chance the monetary viability of your undertaking by means of now not making an investment in the most efficient conceivable irrigation apparatus.

“With reference to repairs, be sure you take the precise movements on the proper time to make sure potency is maintained and filters carry out at their complete doable,” says Neethling.

Electronic mail Charl van Reenen and Dexter Neethling at [email protected], or Matt Needham at [email protected].