Avicarvil is a number one poultry manufacturer, processor and store in Romania with an annual farming and processing capability of over 30 million chickens/12 months. The corporate plans to double this capability within the future years via development a greenfield processing plant in shut collaboration with Marel.

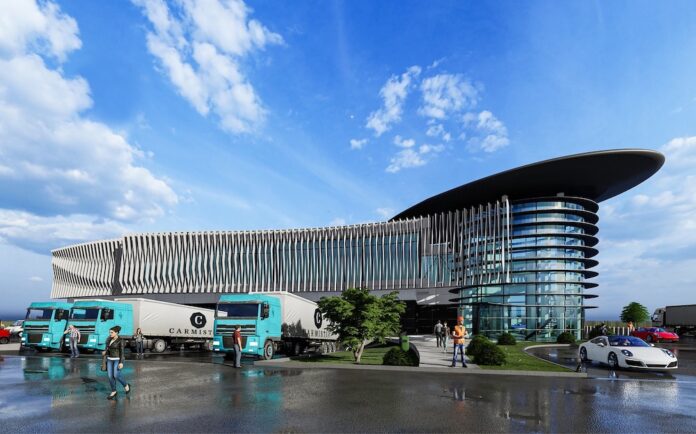

In Vâlcea County, Avicarvil will construct probably the most fashionable poultry processing plant in South-Jap Europe. Protecting a space of 25,000 m2, it is going to be the biggest hen meat manufacturing unit in Romania.

First selection

The Avicarvil plant had to make bigger to verify competitiveness in opposition to global pageant, generating extra hen of upper high quality. Andrei Brumaru, government director of the overarching Carmistin Staff, explains, “For the most efficient effects and the most efficient go back on our funding, we determined to cooperate with Marel. For our new plant, we when compared the potency of the strains in our two present processing crops. Marel’s line used to be obviously awesome and our first option to equip our 3rd processing plant with a capability of 13,500 bph.”

The brand new undertaking

The automatic processing strains come with robotization with Marel’s RoboBatcher. “The RoboBatcher within the filleting line makes a large distinction within the pace and accuracy and guarantees a just right go back on funding. Through combining robotics and instrument, RoboBatcher optimizes the processing time, high quality and protection of our merchandise. As well as, Innova instrument will assist us make data-driven, well timed selections, cut back prices, and build up our competitiveness.”

Sustainability developments

“Our investments goal to mitigate local weather trade. We put into effect programs and applied sciences to optimize power use and water intake. Marel Water Remedy will construct an leading edge gadget for gathering, treating and reusing water, totally complying with the rules in drive. The numerous quantity of recycled water returning will lead to 80% much less water intake,” says Andrei Brumaru.

The method

In Avicarvil’s new plant, the method begins with ATLAS, probably the most sustainable and humane reside chook dealing with gadget within the trade. That is adopted via Marel’s surprising, scalding, plucking and evisceration answers, together with the brand-new, clever Nuova-i eviscerator. The main procedure is monitored real-time via IMPAQT instrument. After blended in-line immersion and air chilling, merchandise are reduce up in two ACM-NT strains and deboned in 3 AMF-i breast filleting programs. Then 5 Multihead Weighers and a RoboBatcher batch and pack the goods. Marel checkweighers and labelers end the method.

Additional information: marel.com/poultry or carmistin.ro